There is a rapidly growing need to make sustainability and circularity transparent and measurable. As a result, circularity has become an important theme on the agenda of the Government of The Netherlands.

The ambition? To achieve a completely circular economy in the Netherlands by 2050. But how do you get there?

Futureproof construction: LCA and ECI become ‘license to operate’

By now, many tenders have an environmental section that obliges suppliers to deliver quantitative environmental performance from products and projects.

The Life Cycle Assessment (LCA) and Environmental Cost Indicator (ECI*- MKI in Dutch) methodologies have, therefore, become well-known concepts within construction.

This means that in the near future, we will see that supplying sectors- including the Public Lighting (*OVL in Dutch) sector- will have to work with these methodologies in order to continue to serve the Dutch government. More and more municipalities will request environmental data- specifically the ECI- in their tenders.

The Frontrunners

When it comes to public lighting, there is still a lot of unclarity on which materials are used for luminaire production and how these materials contribute to the product’s environmental impact. Which materials are good for the environment? Which materials have a negative effect? How does recycling influence the sustainability of your product? Do my material choices influence the lifespan of your product? What should actually be the ideal lifespan?

Licht & Donker Advies (a Dutch lighting consultancy firm) sought out help from Ecochain and together we started the frontrunner project ‘Measuring Circularity – Luminaires & ECI’ in 2018.

The project

In the project, four luminaire suppliers and seven municipalities joined forces to make circularity truly measurable.

In the past, public luminaires were always purchased on a value-for-money basis. Luminaire suppliers would claim they offer sustainable products- but didn’t have the data to prove it. The participants of the project thought this had to change and all recognized the importance of ECI in this process.

Therefore, the aim of the project was to gain more experience with LCA as an instrument- and especially with its main result: the ECI. Regardless of the environmental outcomes, the project was initiated to be an incredibly valuable learning project for all parties involved.

The participants of the project:

- Luminaire Producers: Innolumis, Lightronics, Modernista, Orange Lighting.

- Governmental Institutions

- Dutch Municipalities: Amsterdam, Groningen, Stadskanaal, Nijmegen & Zwolle.

- Provinces: Provincie Gelderland & Provincie Noord-Brabant.

A manual for the ECI

LCA and ECI are not everyday concepts that everyone immediately understands. Many people experience the matter as complex. At Ecochain we would like to do something about that.

To help the public lighting sector get going, Ecochain created a ‘Manual to ECI’ that makes the concept tangible and concrete – completely tailored to the sector. Enabling rapid integration.

This guide helps governments and suppliers with setting up ECI requests and the preparation of setting up a Life Cycle Assessment for luminaires. The theme ‘circularity in public lighting’ is central. The document (in Dutch) includes:

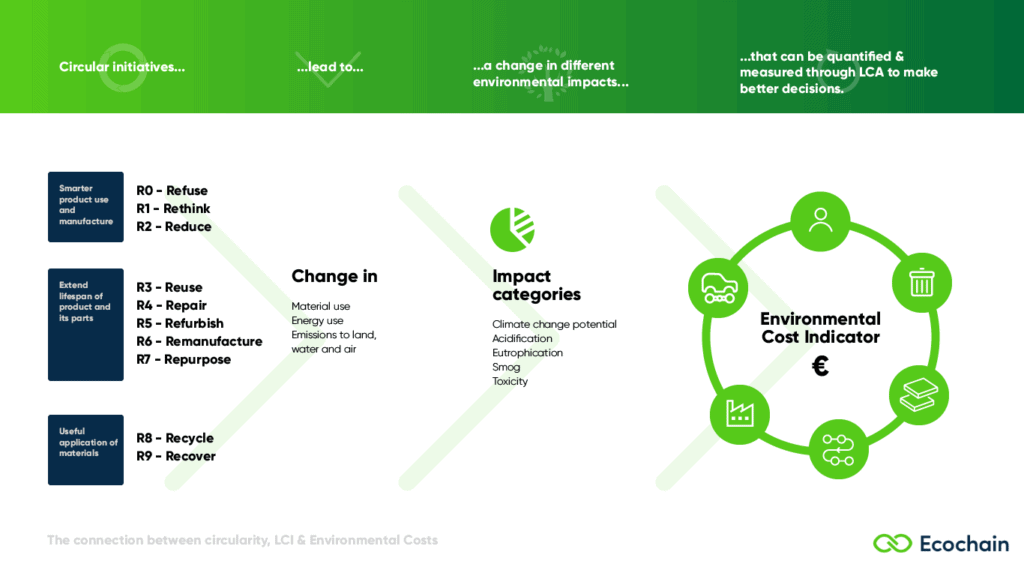

- A brief explanation of the synergy of circularity, life cycle assessments, and the environmental cost indicator (ECI).

- Step-by-step plans for ‘circular procurement’ for governments and ‘circular production’ for suppliers and producers of luminaires.

- Insight into the environmental impact of luminaires with visualizations of extensive scenarios.

With the manual, both clients and suppliers can get started with circular purchasing and ECI. You can receive the manual (in Dutch) for free by sending an email to beatrijs@lichtendonkeradvies.nl and mentioning your name and company/organization.

But first: What are LCA & ECI?

A Life Cycle Assessment (LCA) is a scientific method used to calculate the overall environmental impact of a product over the product’s entire life cycle of products and activities. The method is anchored in ISO standards, on which in turn the European and Dutch standards are based.

The environmental cost indicator (ECI) is a result of an LCA. In short, the ECI expresses the total environmental impact of a product, or a project in excavation, road building, and hydraulic engineering- in Euros. The ECI is the sum of 11 different environmental impacts that occur in the life cycle of a product. It represents the social costs that need to be made to compensate for the environmental damage of the product on the basis of existing (technical) solutions.

ECI is thé KPI in construction that allows contracting authorities to objectively assess and compare the environmental performance of products and projects.

For the Dutch Government and other governmental institutions, LCA’s and the ECI (Dutch: MKI) value of a product have become an indispensable tool to achieve their objectives in the field of sustainable and circular procurement.

The Frontrunner Project – Luminaires & ECI

Beyond recycling

Circularity goes far beyond recycling. During Ecochain’s leading project with the four luminaire suppliers and seven municipalities, the various life stages of luminaires were analyzed in detail by performing LCA’s. Think of the extraction of crucial raw materials, the design and production process, and the use phase of a luminaire. This includes: depletion of raw materials, energy consumption, and the release of toxic substances of interest.

The LCA results demonstrated exactly what the impact of luminaires are on the environment- and where there is room to improve.

In short, circular thinking isn’t just recycling your products. It’s gaining insight into the overall environmental impact of your product- and improving it where needed. Circular thinking is relevant for the entire life cycle and requires the attention of all stakeholders in the value chain of luminaires.

Eventually, results of the product LCA’s were rolled out which the suppliers could use to improve their sustainability and/or demonstrate it to the municipalities. In turn, the ECI allowed municipalities to make insightful and sustainable decisions when choosing suppliers for projects. A win-win situation.

Project results

All 4 suppliers involved in the project had a lower ECI score than they expected. The results of the project created new benchmarks for the municipalities and governmental institutions involved.

The main learnings

1. The choice of material for the housing of a luminaire has a significantly large contribution to the environmental impact.

The material choices contribute to a large part of the product’s overall ECI score. The better and more durable your material choice, the longer your product will remain functional and intact. This also means that the ECI score of the luminaires will differ depending on different lifespan scenarios.

The longer the lifespan of your product, the better your ECI score will be. In other words; when purchasing luminaires sustainably, the required lifespan of the product is a crucial starting point. Furthermore, if you use recycled materials in your production- this will also lower your ECI score. The function, location, and maintenance ultimately also affect the ECI value of a luminaire.

2. If the government wants to ensure a high degree of circularity- then the purchase of renewable energy is essential.

Green energy ensures that the total contribution to the environmental impact of materials becomes more dominant. This makes it easier to create a positive business case with regard to the circularity of the materials and components used in luminaires.

Let’s assume a luminaire has a lifespan of fifteen years and an aluminum housing. If governments decide to buy green electricity instead of grey electricity, the share of the production phase on the total impact increases from about 55% to as much as 80%. The impact in the use phase actually decreases thanks to the beneficial impact of green electricity. In other words: as a supplier, you want to have already identified what the winning circular materials and product designs are in advance.

3. Baseline measurement and hotspot analyses – The information necessary for sustainability.

With input from the suppliers, the most important components and materials in the luminaires were identified and a hotspot analysis of the production phase was drawn up. This hotspot analysis revealed which materials make the largest contribution to the overall environmental impact within the production phase. These outcomes gave the suppliers insight into which materials they can focus on if they want to take further measures to reduce the environmental impact of their luminaires.

The earlier the impact of materials is taken into account in the design process- the more effective it is in the end. Ecochain drew up a baseline measurement for all participating suppliers. By doing so, the producers can get started with making their luminaires more sustainable. Thanks to the project ‘Measuring Circularity’, all parties involved and the most important stakeholders in the luminaires value chain, now have more control over their sustainability and circularity. The ECI Manual provides tools for contracting authorities and for luminaire suppliers and producers to get started with circular initiatives that can really make a difference.

Becoming future-proof: Improved steering on circularity

Ecochain software made a database available in its application for the luminaire suppliers of this project. It contains about 40 common materials and parts of a luminaire. These are linked to environmental references from environmental databases, such as the National Environmental Database (Dutch: NMD).

This significantly increases the ease with which suppliers can make an ECI calculation of their luminaires. Additionally, reference values have been determined from model luminaires. This has been done to determine what the common ECI of luminaires is at the moment and what score is realistic for governments to require in tenders.

The market has been challenged to think about sustainability and circularity throughout the life cycle of a luminaire. In a number of workshop sessions, the most realistic possible starting points have been established with participating parties for the scenarios of the use and demolition phase. Furthermore, the current possibilities for recovery of materials and recycling were also considered- with reference values, clients can better focus on circularity.

Conclusion

By gradually requesting an ECI and lowering it, producers will be challenged to produce circular luminaires that have less impact. Because of the project, governments now also know where their own share lies and how they play a part in reducing the ECI of luminaires. Purchasing green energy has simply become a ‘no-brainer’.