Fashion is fast. Beautiful. And incredibly dirty. That’s what we get told.

But MUD Jeans doesn’t accept that. In 2013, they started the company with a clear goal in mind: Changing the fashion industry – for the better. Today, MUD Jeans even sells the world’s first 100% circular jeans.

This is the story of how MUD Jeans:

- Measures the impact of their different styles & washes;

- How they improve their own environmental performance;

- How their products compare to their competitors.

Sustainability is a mindset

For MUD Jeans, sustainability is a mindset. Even though they are much smaller than the big denim brands, it’s a matter of responsibility. They started calculating their first footprints in 2015 – back when they didn’t use recycled cotton.

In the meantime, many things changed: Suppliers, materials, and processes improved largely over the course of the years.

In 2019 it was time to recalibrate and calculate their footprint. Now – they do it annually.

Methodology: What & How

MUD uses Ecochain’s portfolio footprint tool Helix to fulfill three main goals:

- Continuity: Annually measure the environmental footprint of their complete product portfolio, using the scientific method Life Cycle Assessment;

- Portfolio analysis: With Helix, they want to measure the exact footprint of all their products – and find out specifically what style of jeans causes which impact.

- Benchmarking: Compare MUD Jeans to their competitors. How would their circular jeans compare to other products in the market?

How do you measure the environmental footprints of products?

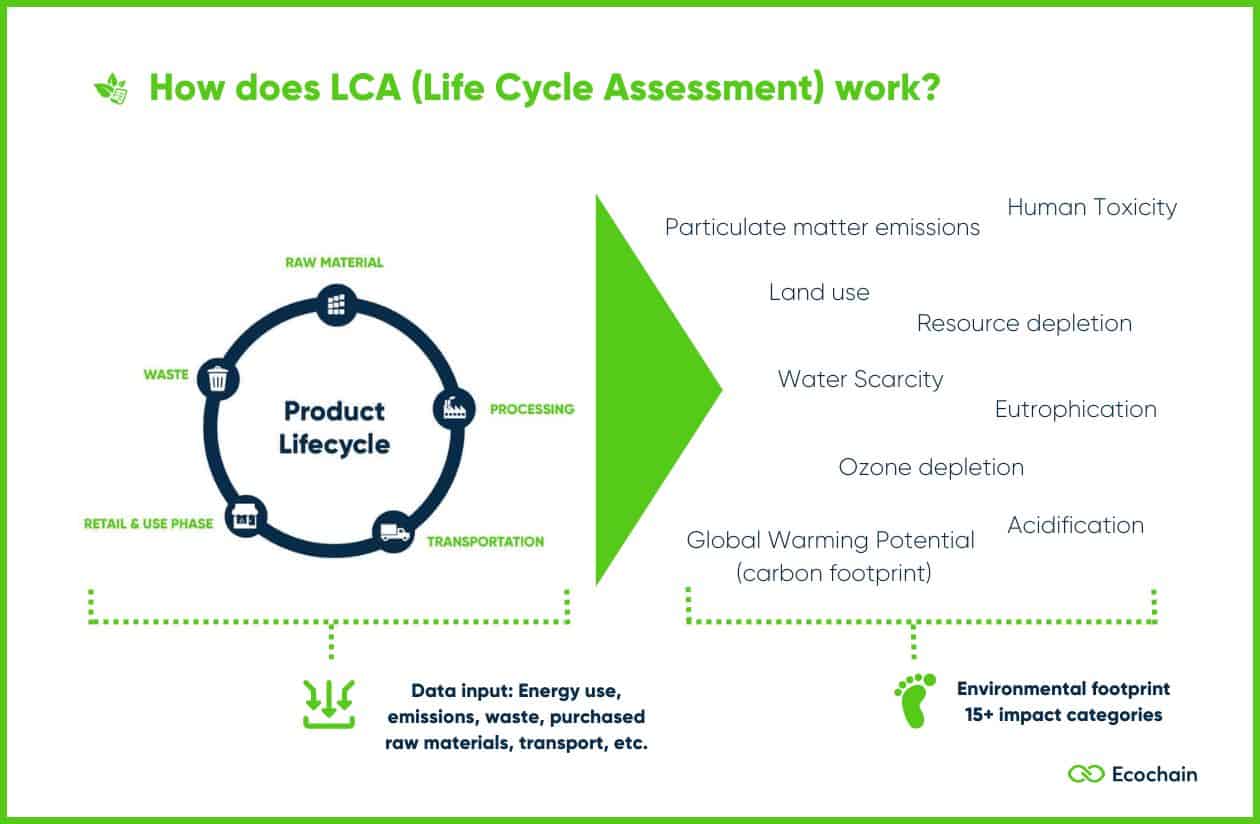

The standard scientific methodology to measure the environmental impact of a product is a Life Cycle Assessment (LCA). LCA measures the environmental footprint of every phase in your product’s lifecycle (from production to waste/recycling/upcycling).

LCA results show 15+ impact categories for every phase in your product’s lifecycle. For the sake of simplicity, most of the results in this case study show the impact category Global Warming Potential – also called carbon footprint, expressed in CO₂-eq.

In the LCA, MUD Jeans relied on ReCiPe – an impact assessment method that translates emissions and resource extractions into aggregated categories.

Cradle-to-Gate: From harvest to factory gate

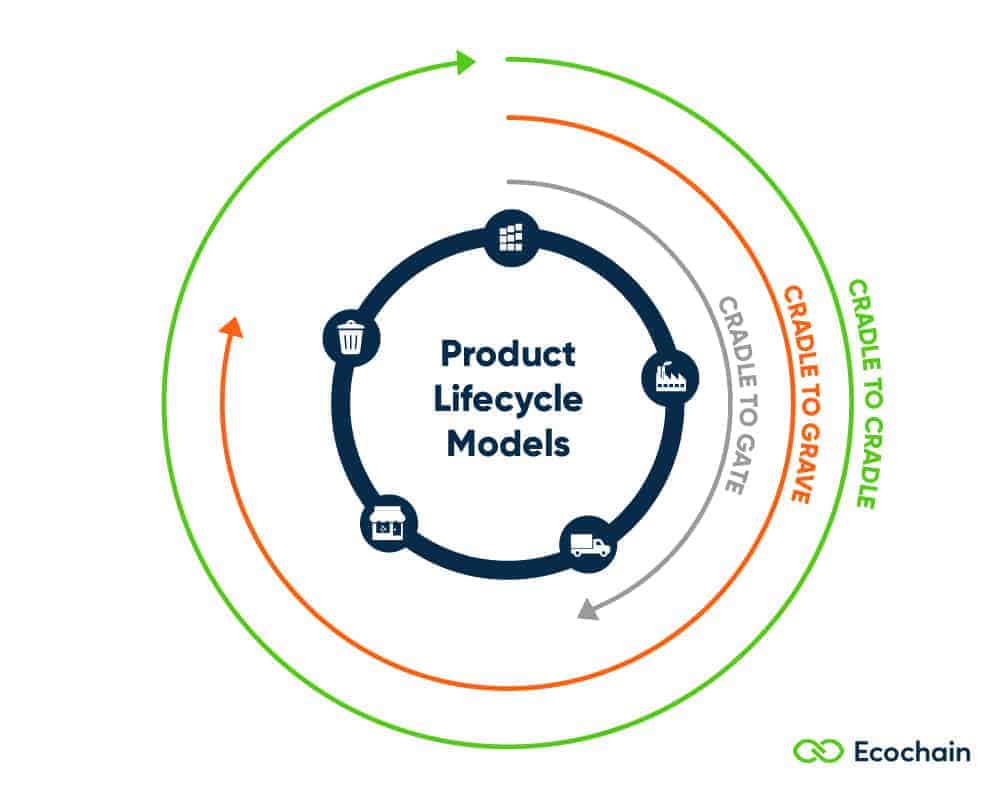

In LCA, you can choose different scopes in which lifecycle phases you want to include in your LCA (image below). Of course, jeans get washed by their users. And washing requires energy. But in this analysis, MUD Jeans focused solely on the impact of their products “from Cradle to Gate”, so until the product gets shipped to the retailer or customer.

The results

The LCA results for MUD showed 5 main insights in terms of environmental impact, benchmarking & biodiversity. These results are from their 2019 LCA report. Since then they recalculated their environmental footprint:

- Find the full 2020 LCA report here.

- Find the full 2021 sustainability report here.

- Find the full 2022 LCA report here.

1. Biggest impact hotspots: Cotton production & production processes

With 42%, the LCA showed that both the production of raw materials and the manufacturing processes have an equal share in MUD Jeans’ overall impact.

a. In the raw materials, the production of organic cotton accounts for the biggest share (36%) of the overall impact of MUD’s jeans collection.

In comparison, recycled cotton has a significantly lower impact. This is mainly because of the use of diesel and water for cotton harvesting – which is significantly higher for the production of organic cotton. When you use recycled cotton, this impact of production is significantly reduced of course – as no new cotton is produced.

b. In manufacturing, continuous drying (22%) and spinning and weaving (22%) account for the biggest impact chunk.

Deep dive: The impact hotspot of one pair of jeans

Ecochain Helix allows companies to also dive into the individual impacts of products. MUD Jeans are made up of certified organic cotton and recycled cotton only.

When zooming in on one pair of jeans, the “Skinny Hazen – Dip Dry” style of jeans showed a clear hotspot of environmental impact. (images below)

The total impact of one Skinny Hazen jeans accounts for 6,3 kg CO₂-eq – that’s about 300 cups of coffee, or 1,2 steaks. Not too bad for a product that will last you a long time, thanks to its quality! Its impact hotspots are:

- #1 impact hotspot = Raw materials. With 53% of the total carbon footprint, the materials used accounted for the majority of the carbon footprint. The use of organic cotton alone accounted for more than half of the total impact! This is not surprising, as the jeans consist of more than 75% organic cotton.

- #2 impact hotspot: Production processes. With 45%, the production processes are a very emission-heavy part of the value chain – with the biggest share of impact in the ironing process.

- #3 impact hotspot = Transport. Transport only accounts for 2 % of the total carbon footprint.

2. 82% of water consumption comes from the raw material supply chain

MUD Jeans truly cares about the water depletion their products cause along the value chain. They already have a very low water consumption compared to other industry brands (see point 4 ‘benchmarking’). But want to reduce it every year. The LCA results show that 82% of the total water consumption comes from their raw materials supply chain. More specifically:

- 75% of water consumption comes from the production of organic cotton

- 22% comes from fabric loss in the production processes

3. The wash and style of jeans influence the impact

Comparing the different styles and washes helped a lot to understand which processes drive impact for MUD Jeans.

One core concept behind MUD Jeans is that different styles are created through different washing techniques. MUD Jeans uses a very limited amount of different fabrics, which get used across many different styles. Using limited amounts of different fabrics helps reduce waste in the production process.

The LCA shows the environmental footprint of their model “Dry Spirit” washing technique is less than 22% of the “Whale Blue” wash!

4. Benchmarking: MUD Jeans emit 66% less CO₂-eq than a comparable product from Levi’s

The analysis paid off. By measuring their impact, MUD Jeans can now compare their products to the industry standard. And they’re doing pretty well.

A pair of jeans from MUD Jeans emits 66% less CO₂-eq than a comparable product from Levi’s. The water footprint is 80% lower, and land occupation 48% lower!

5. Biodiversity at MUD Jeans: 57% better than the industry standard

Biodiversity is considered one of the biggest threats to humanity. Since 1970, the planet has lost more than 52 percent of its biodiversity. 80% of its wetlands. MUD Jeans wanted to understand how they can contribute to a healthier ecosystem on our planet.

Within the calculation methods of ReCiPe it is possible to calculate the endpoint ‘Ecosystem’ in ‘species per year’.

MUD Jeans compared different models based on their biodiverse performance. They found that their Regular Dunn True Indigo model performed a staggering 57% better than the industry standard.

On average, MUD Jeans have a 46% lower biodiversity impact than the industry standard!

100% circular and beyond.

With their LCA results, MUD Jeans can continuously measure their progress and innovate their products. Their impact hotspots show them exactly where they have to focus their sustainability efforts for maximum impact reduction.

Now that they have set a benchmark, MUD Jeans is improving its performance every year. Which means innovating their business model too. Less than 1% of the materials used to produce clothing are recycled into new clothing. The business model behind fast fashion is incredibly wasteful. Their program “Lease A Jeans” pioneered circular innovation in the fashion industry. And it’s a big success.

Read all about their latest LCA results & efforts in their 2022 LCA report.

Measuring LCAs at scale was never this efficient. Experience it yourself.

GET A HELIX DEMO