In this case study you’ll find:

- Why readily available environmental information confers a competitive edge to construction-related producers.

- How Ecochain Helix enables large-scale producers to conduct and verify product-LCAs in bulk.

- The difference between EPDs and environmental profiles – and how the latter communicates LCA results effectively and cheaply.

- Why and how Wavin created 39 EPDs, valid for 390 products.

- Wavin’s key LCA takeaways and sustainable actions

Meet Wavin – Creators Of Healthy And Sustainable Environments

Wavin, the Building and Infrastructure Business Group of Orbia, is a global player in the building and infrastructure industry. The creation of healthy and sustainable living spaces is a vital part of their company identity. Producing in 65 production sites on four continents, their global clientele includes, amongst others, construction companies, wholesalers, and municipalities from about 80 countries.

In collaboration with municipal leaders, engineers, and contractors, Wavin realizes building and infrastructure projects, fostering the climate resilience* of urbanscapes and buildings worldwide.

*For example, collecting, storing, and channeling water protects us from flooding – something our Dutch readers may appreciate.

What Can Life Cycle Assessment Do For A Global Player?

In construction and infrastructure-related industries, sustainability and especially climate impacts are increasingly taking center stage. Construction companies are seeking to evaluate the sustainability of their endeavors and make informed, eco-conscious decisions. Regulation is gaining traction to limit the sector’s enormous climate impacts. The success of these efforts depends on the availability of reliable environmental data on the products and processes employed in the sector.

Having readily available Global Warming Potential (GWP) data on a product level can confer a competitive edge to manufacturers, as clients often require quick access to such information. Moreover, within the Dutch construction sector, the Environmental Cost Indicator (ECI) is used as an important criterion, for instance, to determine the winning bid in public procurement tenders. Construction companies may prefer suppliers that can provide them with the environmental data they need.

Recognizing their customers’ need for environmental data, Wavin embarked on their LCA journey. Their goal? Ready to share environmental data – especially the GWP & Environmental cost indicator (ECI) – on their global product portfolio by 2025. All the while gaining insights to make their products more sustainable. This case study covers phase 1 of the project – assessing 13.000 products of the EMEA product portfolio.

Creating 13.000*2 product LCAs with Ecochain Helix

The basis for environmental data, such as the GWP or ECI of a product, is always a Life Cycle Assessment. However, when aiming to assess a global product portfolio, the conventional “one-product-at-a-time” approach to LCA would take a lifetime to complete.

Instead, Wavin used Ecochain Helix – LCA software developed for large-scale manufacturing companies. Helix employs ”Activity-Based Footprinting” (ABF) to create LCAs in bulk for a factory’s entire product portfolio. The ABF process went like this:

- Creating factory models

First, Wavin’s project manager Matteo Tagliaferri (Specialist Global LCAs/EPDs), supported by three of our environmental specialists, modeled the 23 factories of the EMEA region in Helix. This entails quantifying inputs and outputs of the site – for example, energy-, water-, material-, and fuel-inputs, and emissions. The assessment scope was cradle-to-gate plus waste treatment: detailing the environmental impacts from raw material extraction, to manufacturing, to end-of-life processing, and including materials’ recycling potentials. - Assessing impacts

Then, Helix calculated the factories’ environmental impacts from the models. For Wavin, it was crucial to follow both the “EN15804 +A2” method for calculating impacts – which sets the methodology for LCAs in the European construction industry – and the NMD “Bepalingsmethode” – used to obtain the ECI for the Dutch construction industry. Both methods measure various environmental impact categories next to the climate impacts, giving rise to a complete environmental product footprint. - Allocating impacts over product portfolio

In the final step, Helix allocated the factory’s total environmental impacts over their respective product portfolio. The project team opted for a phased approach, where a few factories are assessed at a time. In this way, the results of the first 6 sites were available after half a year, providing valuable environmental insights. Overall, assessing 13.000 products according to two impact-assessment methods yielded 26.000 individual product LCAs.

Bulk LCA verification in Helix

Verification is recommended when using LCA results in external communication. It ensures the correct application of the LCA standard and that the results can be compared to other LCAs following this standard. Because Wavin’s goal was to use their LCA results in external communication, the 26.000 LCAs needed to be verified.

The external verifier was SGS search. But before you send them your condolences for the hellish workload – let us introduce you to the bulk-verification process supported by Ecochain Helix.

When using ABF, it is not necessary to verify each single LCA report resulting from a factory model. Instead, the factory model itself is verified – the verified status then extends to all LCAs that result from this model. Thus, SGS verified “only” 23 factory models.

Verification is usually valid for 5 years. In case of major changes to a factory, re-verification can be performed earlier.

Environmental Profiles Communicate LCA Results

A very effective way of communicating LCA results to customers is by using “Environmental Profiles.” Environmental profiles are short PDF documents detailing a product’s main LCA results, verification status, and additional product details. Their at-a-glance characteristic makes them perfect for environmental reporting and client communication.

Environmental profiles can be automatically generated within Ecochain Helix at the product level and bulk-exported. This streamlines the process of creating concise materials for environmental reporting.

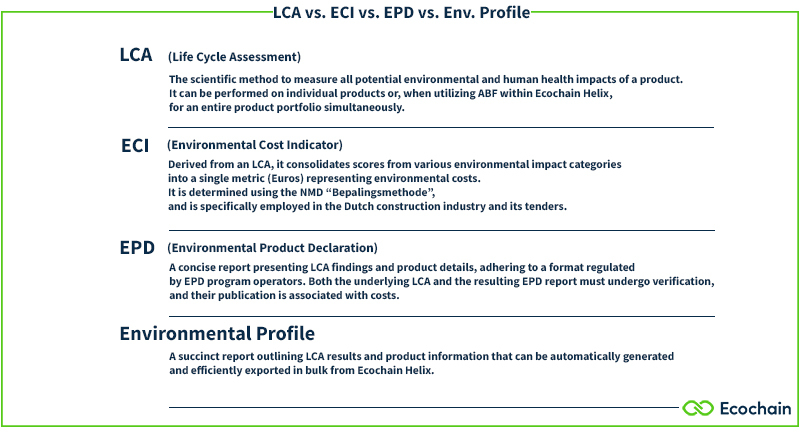

Environmental Profiles vs. EPDs

The environmental profiles described above might seem familiar if you’re acquainted with Environmental Product Declarations (EPDs). They are quite similar – even at Ecochain, we used to internally refer to environmental profiles as “EPD summaries.” Nevertheless, strictly speaking, environmental profiles are not EPDs. To avoid contributing to the convolution of LCA terminology, we want to be clear about the distinction here.

Both EPDs and environmental profiles are based on an LCA, and provide its main messages at a glance. But EPDs need to be individually drafted and verified, and publishing is associated with fees – there are strict regulations by EPD program operators. Environmental profiles are produced at no extra cost and almost no effort in Helix – publishing is free.

Unfortunately, in the construction industry, the term “EPD” has become somewhat of a colloquial expression for any document that offers a quick overview of LCA results, such as the GWP. Consequently, clients might request an EPD when, in fact, all they need is data on a product’s GWP. As long as there is no strict regulatory requirement for an EPD*, environmental profiles effectively serve the same purpose, at less effort and expense.

*EPDs are mandatory in building assessment schemes such as LEED, BREEAM, and GreenStar.

Selective Creation Of EPDs

As explained above, EPDs are rarely required in the current regulatory landscape. In most cases, environmental profiles communicate relevant product data – such as the GWP or ECI – just as efficiently. However, publishing official EPDs has some added benefits!

Publishing EPDs on program operators’ websites, such as EPD Norge or the NMD database, can increase a company’s visibility to sustainability-minded (potential) customers. Such customers might use these platforms as anchor points to find suppliers that have the environmental data they need.

For this reason, Wavin wanted to publish EPDs for selected products. Nonetheless, considering the extra effort and expenses linked to EPDs, the task at hand was to generate a limited number of EPDs – as cost-effective as possible.

39 EPDs, Valid For Hundreds Of Products

The project team aced it here: they crafted EPDs with broad coverage, such that each EPD is valid for an entire product category. For example, by assessing 1 kg of “pipe type x”, the EPD encompasses all variations, irrespective of shape and size, within that category, as long as the materials, production methods, and product characteristics are consistent. Then, EPD data can be computed for each product within the group, based on its weight.

They developed 10 EPDs according to the EPD Norge standard, which required some additional calculations on top of the EN15804 +A2 LCA results. Furthermore, they crafted 29 EPDs according to the NMD Bepalingsmethode 1.1. These 39 EPDs encompass product categories containing approximately 1-100 products each. As a result, a total of about 390 products now have valid EPDs.

Making LCA Result Count

Matteo Tagliaferri (Specialist Global LCAs/EPDs) continues to be the gatekeeper of the environmental profiles for internal and external use. Environmental profiles and EPDs are shared with customers on request.

Furthermore, Wavin shares the acquired LCA data across various e-commerce platforms. Depending on the platform, the data format can span from GWP reporting, to results for a cradle-to-gate scope, to comprehensive environmental footprints. The EPDs are also published at the respective program operators.

Ongoing initiatives aim to seamlessly integrate LCA data into construction software, such as Building Information Modeling. This will simplify access for various stakeholders in the construction industry. The 29 Dutch EPDs are integrated into the DuboCalc Tool, which is used by, amongst others, public authorities to make environmental assessments of entire public road and infrastructure projects in the Netherlands.

Internal Use of LCA Results

Internally at Wavin, the LCA project inspired a slew of sustainable actions!

Switching To Renewable Energy

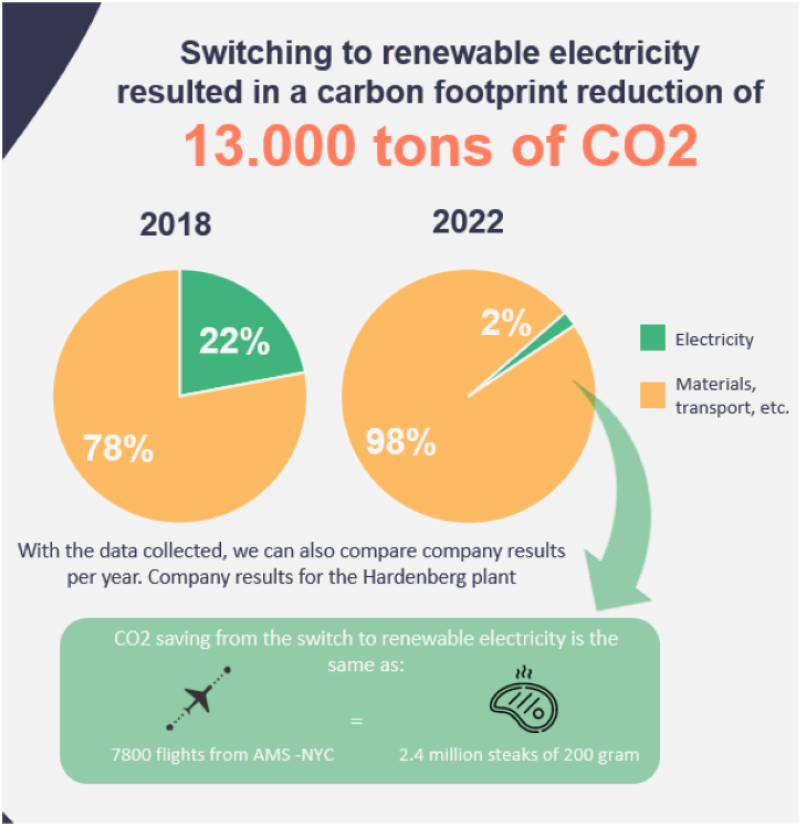

Switching to renewable energy sources across all European production sites reduced manufacturing emissions and the footprints of hundreds of products simultaneously.

Annual factory footprint comparisons in Helix allow for interesting insights. For example, due to the switch in energy sources, the Hardenberg plant emitted 13 thousand tons of CO2 equivalent less in 2022 than in 2018!

Quantifying Sustainability for Product Design

Wavin already knew that raw materials, and especially virgin plastics, are climate impact hotspots in their product portfolio and continues to make efforts to use alternative raw materials, such as bioplastics and recycled materials.

The importance of this endeavor was confirmed by the LCA results. There is ongoing research into alternative sustainable raw materials that simultaneously preserve product properties and functionality (a common challenge in Sustainable Product Design).

Increasing Employees’ Environmental Literacy

LCA gained significance for Wavin’s company identity: now, an internal FAQ raises employees’ awareness and knowledge about LCA and EPDs. Internal training equipped the sales team to communicate Wavin’s sustainability efforts to stakeholders confidently.

Wavin’s LCA Journey Continues…

Presently, Wavin is implementing the LCA project at their production facilities in Latin America and aims to finalize the LCA project, which will include facilities in Asia and North America, by 2025.

Wavin appeals that sustainability considerations should generally be part of product development. To put this conviction into action, they plan to utilize Ecochain Mobius as a Sustainable Product Design Tool.

Bottom Line

Wavin, a major player in the global building and infrastructure industry, successfully conducted and verified LCAs for their EMEA product portfolio. Ecochain Helix played a pivotal role in executing the project cost-effectively. The resultant environmental profiles offer easily shareable LCA data, making them highly suitable for various customer communication needs. Furthermore, the creation of EPDs for selected products enhances Wavin’s visibility among customers.

By providing LCA data, Wavin empowers its customers to engage in more sustainable construction practices. Internally, the LCA project underscored the significance of using sustainable raw materials and solidified sustainability as central to the corporate ethos. Their LCA journey is an ongoing commitment, expanding to all Wavin’s global production sites and extending into future product development.