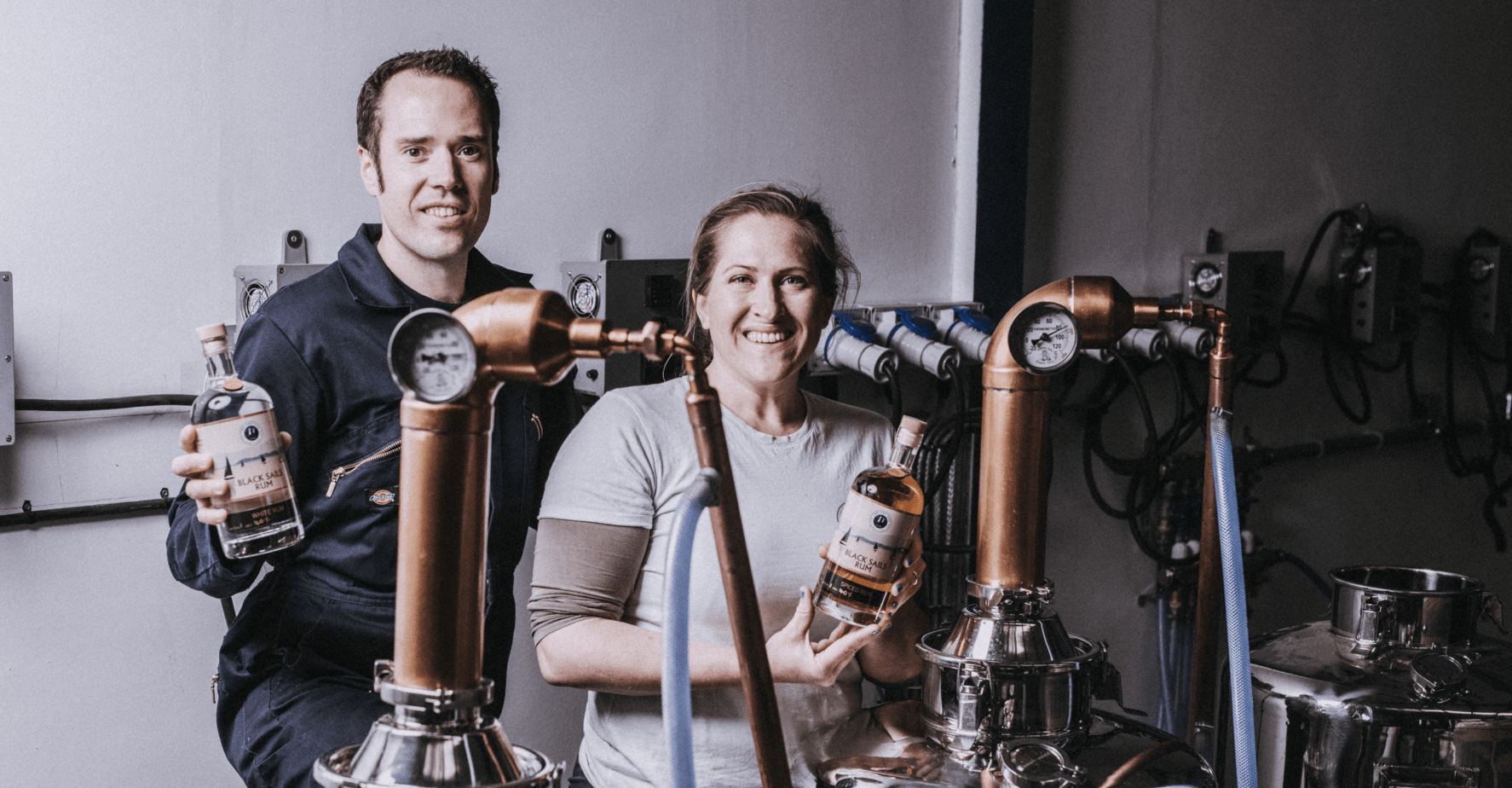

Meet Two Drifters.

Two Drifters is one of the most ambitious projects in the spirits industry.

We love it.

Because when Two Drifters found out that rum could be a viable business for them- they not only deep-dived into the impact of their operations. They designed them to be carbon negative from the ground up.

Putting the pressure on carbon

Two Drifters Distillery was founded by Russ and Gemma Wakeham.

With Russ having a Ph.D. in Organic Chemistry and a background in carbon capture and utilization technologies, the Wakeham’s had the desire to push their love for rum to the next level.

How? By creating an eco-friendly high-quality product and minimizing and offsetting their CO₂ as much as possible. So, naturally- Two Drifters set themselves an internal carbon price of 700 dollars (!!) per ton. To put it in perspective; the EU tax is about 30 dollars per ton.

Treating CO₂ as waste product

Two Drifters continuously performs extensive LCA’s with Ecochain and keep revising and improving their environmental footprints. They also made the decision to overcompensate their remaining impact, by paying Climeworks in Switzerland to capture and offset their CO₂.

The trick to their success? It’s a change of perspective. You see, Russ is a firm believer that CO₂ should be considered a waste product.

How does treating impact like waste, influence your manufacturing decisions?

Tthe answer to that is quite simple: a lot. Because if you treat CO₂ like a waste product, you should also clean it up after yourself. To do so, means you have to increase every type of control you have on your waste.

When we were interviewing Russ for our Frontrunners Report: ‘ Spirits of the Future’ he told us this:

The one single thing we have influence over, is our distillery. Everything is electric. All the stills and everything else. We burn no gas.

Russ Wakeham

Which is interesting. If you try to make manufacturing decisions in which you create your own electricity, recycle your own heat, and try to keep your emissions as close to home as possible. At least you will have more personal influence over the ‘waste’ you’re putting out into the skies.

Rethinking and redesigning your business processes to make them sustainability-proof, is the best way to make your business model future-proof too. Still, the amount of work it takes to do that as a large spirit company is quite frightening and challenging sometimes.

What does Russ have to say about this?

The biggest challenge: Redesigning old processes

In the case of Two Drifters, they completely redesigned their former bigger brewery, which also brewed beer, into a rum-only brewery. They converted their brewery equipment into a larger still. All completely electric and with a negative carbon footprint through carbon capture. They set new processes from the ground up.

You see, converting old equipment into new processes is quite expensive. However, if you (re)set your processes from the beginning with the intention of having sustainability embedded in their core- Russ states that he doesn’t see how that would cost more.

Therefore Russ’s advice is: setting up a carbon-negative business is more efficient if you do it from scratch than if you do it by refurbishing old processes.

It’s a complicated issue, because it’s just not so visible. A piece of plastic in the ocean is easy to understand. But you can’t show a piece of CO₂ in the atmosphere. It’s just so easy to dismiss.

Russ Wakeham

Finally: Tackling Water

Distilling liquors comes down to two core factors: water & energy. Two Drifters already tackled the energy part. Now let’s see what they did when it comes to water.

First, they use a reverse osmosis system for purifying their water. As the water in their region in the UK is quite hard, it needs to be purified either way. However, they then repurpose this purified water to cool their stillers through a water cooling system. All electric of course.

The chill-stiller system is also a closed circuit. This way, when it’s hot they can just reuse it and pump it into the next batch whilst also saving the energy they used.

Finally, Two Drifters uses a heat exchange to generate the cleaning liquid for the systems as well. Making their cleaning process the dead-end when it comes to water.

Interested in reading more success stories of sustainable frontrunners in the spirits industry? Download our first free Frontrunners Report: ‘Spirits of The Future’ for many more insightful stories of companies that are making the spirit industry more environmentally friendly.