Life Cycle Assessments (LCA) following “Cradle-to-Gate” – measure a product’s environmental footprint up to the point where it leaves the factory gate. This means the environmental footprint results don’t include the footprint of product use by customers and its end-of-life processes (waste/recycling/upcycling).

Cradle-to-gate simplifies and speeds up the LCA process. This is handy in certain situations – as you don’t always have data on what happens after your products go out of the factory doors. For example, chemicals or textiles can be used in multiple applications after they leave the factory doors.

In this article you’ll learn:

- What LCA-Life Cycle Models do

- What Cradle-to-Gate looks like in LCA

- When to choose Cradle-to-Gate in LCA

Cradle-to-Gate is a “Life Cycle Model” in LCA

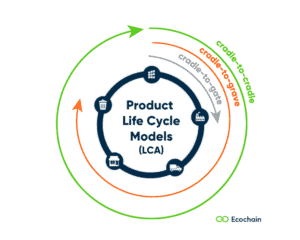

You most likely heard about Cradle to Gate in the context of Life Cycle Assessments (LCA). LCA is the scientific method to measure all potential environmental and human health impacts of a product. Its scope (which phases in the life of your product the LCA actually looks at), is determined with a “Life Cycle Model”. And Cradle-to-Gate is one of several Life Cycle Models.

Life Cycle Models determine what your LCA looks at

An LCA is like a magnifying glass: it makes you zoom in on every detail of your product’s environmental footprint. Here, Life Cycle Models determine which product life cycle phases you apply that magnifying glass to.

Most products go through the following life cycle phases:

- Raw Material Extraction, also called the “cradle”

- Manufacturing & Processing

- Transportation

- Usage & Retail

- Waste Disposal, also called the “grave”

LCAs determine the environmental impacts of some, or all of those stages – according to the Life Cycle Model you choose. More formally, this is called choosing the “scope” of your LCA. Or deciding on the “system boundaries” of your LCA.

Main Takeaway: the Life Cycle Model in Life Cycle Assessment, also called its “scope”, determines how many phases of your product’s life cycle (from raw material production until end of life phase) you include in your environmental footprint measurements.

What Cradle-to-Gate looks at in LCA

When you do an LCA according to the Cradle-to-gate model, you collect data and gain insight only into the first two stages in the product life cycle: your raw materials, transport of the raw materials, and production processes. You stop assessing before the finished product is transported anywhere – so before it leaves the factory gate!

Alternative Life Cycle Models

If Cradle-to-Gate doesn’t butter your toast, the following alternatives can be used as your LCA’s scope:

- Cradle-to-grave includes all 5 life cycle stages in your measurements. This gives you the complete environmental footprint, from start to end. (Stages 1-5). It’s the most recommended model – as it gives the most complete footprint results.

- Cradle-to-cradle is a variation of Cradle-to-grave, but exchanges the waste stage with a recycling/upcycling process that makes materials or components reusable for another product – essentially “closing the loop”. (Stages 1-5, with 5 being another product’s Stage 1)

When to choose Cradle-to-Gate in LCA

Companies choose cradle-to-gate as LCA model because:

- It’s easier & faster: It’s easier to collect data on only the first two phases than the data necessary for LCAs on the full product lifecycle (cradle-to-gate & cradle-to-cradle). Collecting data on how customers use your product and how your product is disposed of/recycled/upcycled – is extra time and effort not all companies want to invest.

*Note: the use phase and end-of-life phase in a product’s lifecycle can account for a big portion of your footprint (e.g. up to 20% in the footprint of apparel products). Always aim to include them – when you’re ready.

- It’s a good starting point: As it’s faster – many of our customers first start with cradle-to-gate LCAs for their initial product footprint results. It’s a good way to get the hang of LCA and already gives you great insights into the footprint of your production processes and materials. After that, they perform cradle-to-gate or cradle-to-cradle LCAs for a complete picture.

Use cases

Using Cradle-to-Gate is often used:

- When post-factory-gate processes are uncertain – e.g. your product is input for too many different supply chains. In this case, having an LCA or EPD ready for your customers is handy!

- To create an environmental product declaration (EPD). Those can easily be/are often requested based on Cradle to Gate!

- To compare products that have identical post-factory-gate processes. E.g. a product in different colors. (Be sure they are identical)

Interested in calculating Cradle-to-gate LCAs? Read our in-depth blog on how to make a cradle-to-gate LCA in our easy product footprint tool Mobius.