The average fashion brand drops 4-6 new collections every year. It’s convenient: The large scale allows for higher margins and lower production costs.

But the seasonal drops come with a high price:

It’s impossible to accurately plan how well a collection sells. The result: A battle for rebates, constant sales, and massive overproduction. Some fashion brands go as far as burning their excess stock in order to retain their high prices.

Flow fashion: How 20 drops a year are better for everyone

The concept of Dutch female fashion brand Studio Anneloes has always been the opposite of that: Instead of few, large drops, the company from Amsterdam drops another collection every other week – that means that Studio Anneloes publishes as many as 20 new collections every year.

It seems counterintuitive: How can more collections reduce the environmental impact?

At a closer look, the concept does exactly that: The smaller, but frequent drops, enable Studio Anneloes and their retailers to create scarcity among their product range.

It’s good for the retailers, because the fans of the brand have a reason to come back to the store more frequently. And it’s also good for the customers: Their products retain exclusivity and a high value.

The second-hand market for Studio Anneloes products is booming, with many products selling for 50% of their retail price. And overproduction isn’t a problem.

20 fabrics, 1200 pieces of clothing every year – how do you measure that?

Studio Anneloes is reinventing the way fashion gets manufactured – so they also had to reinvent their supply chain. Frequent drops require the manufacturer and product designers to work very closely together – this is one of the reasons the Dutch brand manufactures close to home in Poland, while sourcing their materials from Italian supplier Eurojersey.

The big challenge: While only using 20 different fabrics, Studio Anneloes creates 1200 different fashion products every year. How do you translate the environmental impacts of so many different products?

How a quality mindset translates to sustainable business

We didn’t start this business with the intention to become a sustainable business. But we quickly realized that what we are doing is inherently more sustainable than what’s happening in the industry.

Jan-Willem van Loon, Co-Owner, Studio Anneloes

But when him and his wife had a dinner with their main supplier, the story took another turn.

Free Download: How to become the world’s most sustainable fashion brand – your quick start guide to apparel that’s good for the planet!

A Dinner and a Box of Environmental Data

“Our supplier Eurojersey opened up and told us that we are now their biggest customer. That was great news for us, and we really didn’t expect it”, says Jan-Willem.

But Eurojersey has always been on the forefront of sustainable fashion, and they had already started calculating the environmental footprint of their fabrics.

Eurojersey told us that that also gives us a lot of responsibility. They care a lot about sustainability, and so did we. But we had never measured our footprint before. So they gave us the figurative box with their environmental footprint data – and now it was our turn to be a part of the chain.

Jan-Willem van Loon

How do you turn Data into insights?

This meant that Studio Anneloes had to make sense of the box of data that their supplier offered to them.

That’s when they turned to Ecochain for help. Studio Anneloes didn’t want to rely on background or average data – they wanted to measure their actual impact.

Connecting the Supply Chain with Ecochain

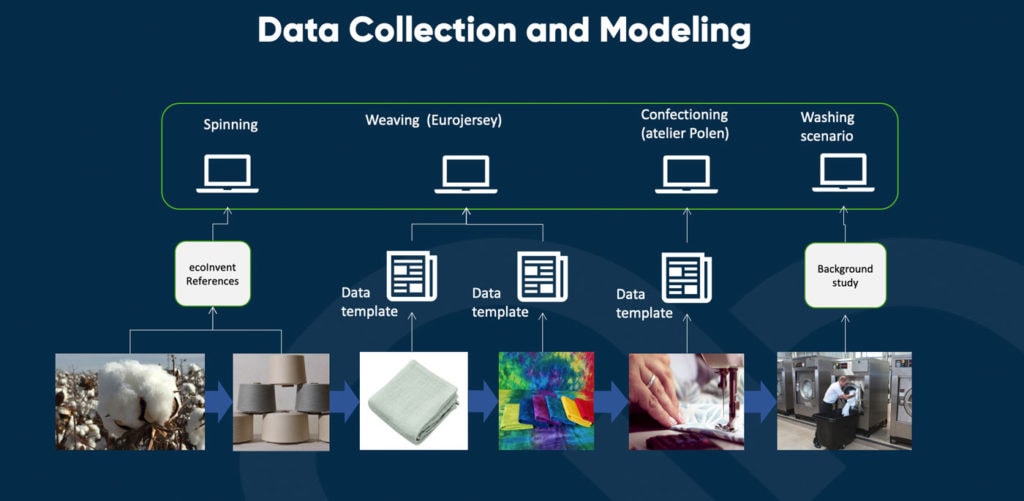

Our Environmental Specialists implemented Ecochain’s tool Helix throughout Studio Anneloes’ value chain. They went to Eurojersey’s Italian faculties in order to measure the supplier’s process impacts. Then, these were connected to the manufacturing facilities in Poland, as well as the transportation processes of the brand itself.

The result was more than just numbers: With Ecochain’s analysis, Jan-Willem and his team could finally make sense of their environmental impact.

Environmental Intelligence integrated into Studio Anneloes’ IT

Through a datasheet, Ecochain’s data was linked to Studio Anneloes’ IT system. This way, the purchasing and production processes of the company can now be informed by the measured environmental footprints.

Communicating the footprint

Studio Anneloes wanted to involve its clients in their environmental efforts. But this required the company to fully understand what they had actually measured. Ecochain’s Environmental Specialists taught this knowledge to the team in learning sessions: What is CO₂? What does water usage actually mean? What is the impact of the different activities?

This helped the company to make informed decisions about the environmental indicators they wanted to focus on.

The role you wear with fashion

One of the biggest surprises: Their own impact was surprisingly low. A much bigger impact: The use phase.

We realized that our customers play a crucial role in our environmental story. Our garments are of the highest quality and last very long. But washing and wearing our products has an impact, and we can actively reduce that.

Jan-Willem van Loon

So, Studio Anneloes went to work and campaigned around the use phase: Wash our clothes less, wear them longer, and take care of them. A survey showed the results of their efforts: Studio Anneloes’ fans turned their advice into action and helped make their products last even longer while reducing the impact through less washing, ironing, and tumble drying.

Small steps towards a more sustainable brand

Today, Studio Anneloes’ Environmental Data is implemented right into their IT systems. That helps the brand to make data-driven environmental decisions on a day-to-day basis.

Since then, Studio Anneloes has invested into reducing their impact even more: A new office building is in construction right now.

A recycling initiative has also helped Studio Anneloes to recycle packaging waste as well as re-use the plastic hangers they use to deliver their products.

Studio Anneloes made sense of their environmental data and turned it into action. But they’re not done.

A price tag, and a carbon tag

Jan-Willem and his team went one step further in their environmental efforts. Every Studio Anneloes product label today has its CO₂ impact printed on the label – including a QR code that enables their customers to learn even more about the environmental impact of their products.

I think it’s our responsibility as the fashion industry to allow our customers to make more sustainable choices. If all brands would be transparent about their impact, we could really help with that.

Jan-Willem van Loon

You can find more about the results of our project at Studio Anneloes’ website under https://www.studioanneloes.nl/footprint/