Cashless culture doesn’t stop in your pocket. That’s why micro-wallets – the card-sized, super-small containers that hold up to 8 cards, have become an established product category

Smaller. Smarter. Quicker and Fashionable.

As consumers want the things they carry to get smaller and more convenient, the pocketwear market has become more and more innovative in creating self-defined pocketwear.

But, does this mean pocketwear is also becoming more sustainable?

Pocketwear brand Secrid stands out: they focus entirely on local production, quality, people, and the environment. And as it is a part of their core values, it seemed more than logical for Secrid to find out what their environmental impact actually is and especially; how they can improve it.

Combining fashion and convenience: Meet Secrid

Secrid is a fast-growing pocketwear company based in the Netherlands. They started out in 2009 selling just a few thousand products per year, however, already sold over 2 million products worldwide in 2019.

The brand is especially known for its smart wallet solutions such as the Cardprotector and the Miniwallet. Each of their products features a patented mechanism that allows you to quickly slide out your cards with one simple motion, making them ready for immediate use.

Bringing leatherwear production back to The Netherlands

Other than creating beautiful products, Secrid is also a locally-focused business. This means that all products of Secrid are 100% made in Europe. 85% of their suppliers are situated in The Netherlands, including the social enterprises at which the products are assembled.

This way, Secrid supports local businesses, keeps its value chain local, and, therefore, also keeps its use of transportation low – a core ingredient to reduce the overall impact of Secrid’s products.

Why measure the environmental footprint of something so tiny?

Within Secrid, sustainability has always been recognized as a core value and a crucial aspect of being in business. And as sustainability awareness surrounding organizations generally increased within society, Secrid also started to ask critical questions about the sustainability of their own practices.

Because of their use of leather, aluminum, and other raw materials that could be considered unsustainable. Secrid quickly recognized they wanted to take responsibility for their impact and start improving their practices where needed.

But to do so, they first needed to understand what their impact actually is.

The Impact Results

In 2018, LCA calculations were performed in Ecochain’s tool Helix to define the impact of Secrid’s business operations and identify the biggest environmental-impact hotspots. The impact calculations were divided into two sections: The Secrid Headquarters and the production chain of Secrid’s products.

All Secrid’s products are designed in-house, however, Secrid does not own any production locations themselves. They thoughtfully select their partners and production methods, but cannot directly influence the production impacts.

The Secrid Headquarters

When looking at the footprint of the Secrid headquarters, the air traveling of employees for visiting fairs generates almost half of their impact on climate change. Indeed, flying has a bigger impact than other ways of transport and utilities.

The Secrid Product Supply Chain

Within the Secrid supply chain, the results show two major hotspots of environmental impact:

1). The impact of leather is high compared to the other materials. This is mainly due to the intensive water use and emissions of greenhouse gases.

2). The use of aluminum in products generates a big impact in several impact categories. The mining of the raw material (bauxite) counts for 84% of the emission of greenhouse gasses for the total aluminum impact. The mining of the raw material also has a big impact on resource depletion. Additionally, the subsequent production steps of aluminum production are quite energy-intensive.

Leather is highly impactful. Here’s how Secrid approaches that issue.

With the LCA results in their hands, Secrid immediately went to work to improve them.

They had long been looking for-and experimenting with – other materials than leather. However, the core purpose of the company remains to create products that last long and age beautifully over time. And so far, leather still seems to be the best material for creating long-lasting products due to its high technical and emotional durability.

Indeed, those two factors are very important characteristics supporting Secrid’s philosophy of long-lasting design. This philosophy entails that they focus on keeping products in use for as long as possible, making sure the moment products are thrown away as well as the production of new products- is postponed. This way, the overall environmental impact of Secrid’s products will be kept low.

Making leather cutting more efficient.

Leather cutting is definitely a waste intensive process. It’s not rare that half of the leather is cut away and wasted in the leather industry.

To decrease this percentage, Secrid generated more efficiency in its leather use in collaboration with its leather cutting specialist Piant. And it paid off.

Since 2016 the efficiency of their leather-cutting process has been improved by more than 22%. Secrid pushed their international suppliers of cutting-machines well above the limits they were used to for their demanding car-manufacturing clients.

However, Secrid and Piant are still looking for improvements in the process and the design of the wallets. Additionally, Secrid aims to improve how they reuse their waste, as they want their waste levels to be close to zero.

Finally, from pre-tanning to finishing, Secrid will increase its efforts to find more sustainable ways of producing leather in the future.

Thanks to Ecochain Helix we generated insight in our impact on the world around us, furthermore, it also showed us on what main activities we should focus in our mission to reduce that impact

Thomas Beekhuis, Sustainable Innovation Specialist at Secrid

Onto the next step: Tackling aluminum waste

To continue their journey towards a zero-waste supply chain, Secrid looked into the reuse of rejected aluminum. As a result:

- Secrid partnered with the Swiss company Freitag to create a product made from worn-out tarps from trucks and damaged aluminum profiles.

- Secrid introduced a product that contains rejected aluminum profiles, the Cardprotector ‘Powder’.

The other option for Secrid to handle the rejected aluminum would be to send it to an external recycler to create new aluminum. However, the external recycling of aluminum is a multi-step and energy-intensive process.

Instead, when Secrid reuses the aluminum internally with one reprocessing technique, new value is added to otherwise not used materials. This makes Secrid’s upcycling process much more efficient than recycling the aluminum.

How COVID-19 turned into an impact-eye-opener

Lastly, even the COVID-19 crisis added some new insights into the business practice of Secrid.

First, the reduction of traveling to fairs all over the world had been an eye-opener. This reduction reduces the biggest share of impact on an organizational level. Therefore, in this changing scenery, Secrid is looking at the reduction of- or alternatives for a part of these flights in the future.

Furthermore, the positive impact of producing locally has also been confirmed in Ecochain due to the low contribution of transport within the supply chain.

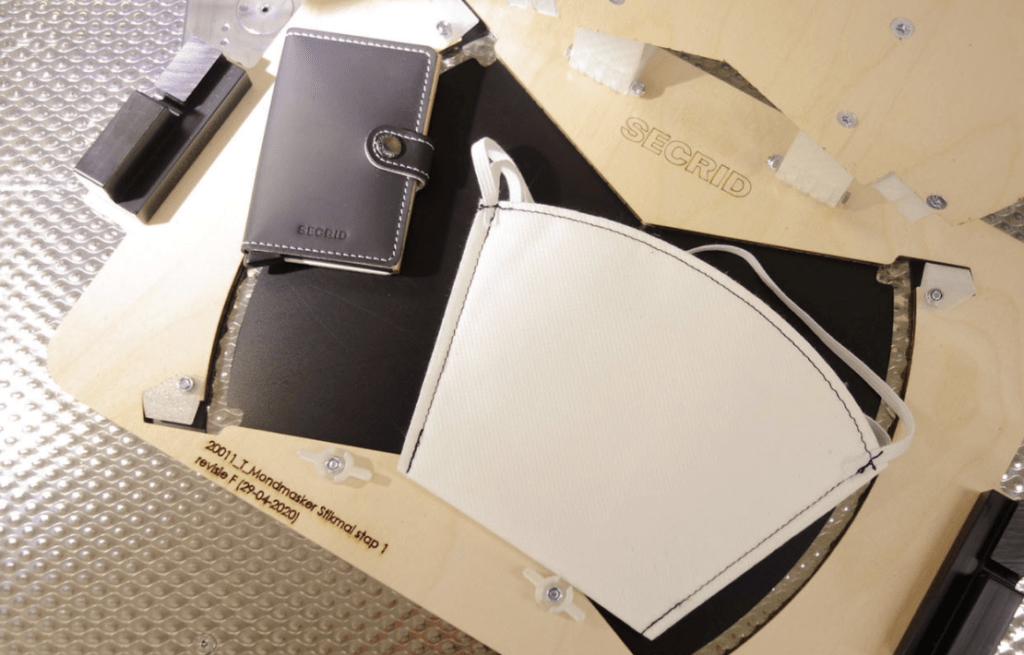

Indeed, during the COVID-19 crisis, the short distances and good connections with the suppliers helped find opportunities to help society. This is exactly what Secrid and its local suppliers did by producing medical face masks for hospitals.

Secrid has a strong internal drive to be a front-runner in sustainability. From the start until the end of the project Secrid was on top of the matter, curious about the background and science behind the methods. Besides their enthusiastic attitude, Secrid also helped with improving our tool and data collection procedure by providing valuable feedback. As a proud owner of a mini-wallet, this project was very tangible and it is funny to realize I’m actually wearing a product LCA that Ecochain calculated.

Luc Hillege, Environmental Specialist at Ecochain

But Secrid is just getting started

Although Secrid can now put a number on the impact they generate, working on their sustainability triggered some additional interesting questions.

For example;

- How would you take the ‘life of a cow/bull’ into consideration for impact calculations?

- To what extent could Secrid be held accountable for the environmental impact of low quality and fake copies of their product available on the market?

Still, so far Ecochain Helix helps them to be transparent about their impact and create an effective sustainability strategy. Secrid will continue to use Ecochain Helix to make comparisons/new calculations for clarity and effective sustainable measures in the future.

Finally, they compensate for their remaining CO2 emissions together with their partner FairClimateFund. And as they did it retroactively products of Secrid are 100% carbon neutral since the beginning in 2009.