TL;DR: Summary of what this article covers

- Choosing an EPD tool is a strategic decision, not just a software purchase. For construction product manufacturers, EPDs now sit at the intersection of tenders, regulation, product strategy, and credibility – and the wrong setup can quickly turn into rework.

- Not all EPD solutions scale the same way. The difference between AI-driven tools or tools offering generic, locked datasets and product-specific, reusable LCA foundations determines whether EPDs stay manageable as requirements grow.

- The most important factors to evaluate in your new EPD generator go far beyond generating a PDF. These include software capabilities, automation, data foundation setup and traceability, verification readiness, scalability, expert LCA and EPD support and services, implementation time, and long-term ROI.

- If you manufacture construction products, building materials, or industrial goods, this guide helps you assess and choose the right online EPD software for your product sustainability goals by showing what to look for in EPD solution and which questions to ask vendors before you invest.

You’re not just choosing an EPD tool. You’re choosing how your company handles product sustainability at scale.

Environmental Product Declarations (EPDs) stopped being a niche deliverable.

For construction manufacturers, they now sit at the intersection of tenders, regulation, product strategy and credibility.

Tenders ask for verified carbon footprints. Customers want credible data. Regulators such as the EU Construction Products Regulation (CPR) and CSRD push manufacturers toward transparency.

Choosing the right EPD generator for your business needs looks like a tooling decision. In reality, it determines whether EPDs become a one-off fire drill or a reusable product impact foundation.

And with dozens of options on the market – from expensive one-off consulting services, to LCA software with built-in EPD generators, to locked or AI-driven standalone EPD calculators – it can be hard to see which approach will actually hold up for your business needs.

Having worked with hundreds of construction manufacturers, and knowing the challenges sustainability, R&D and product teams face day to day, we created this guide to help you understand what to look for when evaluating EPD software – and how to pressure-test both the tool and the service behind it before committing your budget.

When should you use an EPD generator?

An EPD generator makes sense when Environmental Product Declarations are no longer a one-off request, but something your business needs to deliver repeatedly, reliably, and under pressure.

For most manufacturers of building materials, supplies, and construction products, that moment often comes quickly. You publish one EPD for a priority product. Then sales asks for another variant for a tender. Then customers request product-specific data. Then regulations tighten. Before long, EPDs stop being a project and start becoming part of day-to-day operations.

An EPD generator of your choice should be designed for exactly that situation: when you need to publish verified Type III EPDs in line with EN 15804+A2 and related ISO standards, without turning every EPD into a slow, expensive consulting exercise.

An EPD tool embedded in accessible LCA software is likely a good fit if this sounds like your situation:

- You want predictable, transparent costs for EPD generation instead of per-EPD consulting fees that grow with volume.

- You need to generate EPDs for multiple products or an entire portfolio, not just a single report.

- You want EPDs that reflect how your products are actually made, using product-specific and supplier data instead of generic assumptions.

- You have limited in-house LCA experience and want software that guides the process, backed by LCA experts who can review assumptions and data.

- You want expert support before verification, so issues are caught early and verification runs smoothly.

- You prefer one system to manage data, models, EPD outputs and publication, rather than juggling spreadsheets and tools.

- You are able to collect and document your product and manufacturing data and want to keep that knowledge in-house and reusable for future EPDs, PCFs and regulatory requirements.

If your situation still looks like “we only need one EPD”, an EPD generator may feel like more than you need right now. But if there’s even a chance that one EPD turns into ten, or ten into a full portfolio, starting with the right foundation can save you months of rework later.

Let’s go through the most important aspects to consider before you invest in a manufacturing EPD software.

Seven key things to consider when selecting an EPD tool for your manufacturing business

The following 7 factors will help you assess whether an EPD tool will support your business today, and still make sense as requirements scale.

1. Software capabilities – what does this EPD tool actually give you?

When evaluating EPD software, it helps to focus on a specific set of capabilities that directly affect the quality, credibility, and lifespan of your EPDs – not just whether a PDF can be generated.

A good place to start is understanding what kind of tool you’re actually buying.

The six software capabilities that matter most when evaluating an EPD solution:

a) Is the EPD generator a standalone tool, or part of a full LCA software?

Some EPD solutions focus purely on generating the declaration itself using average product CO2 data.

Others are embedded in full LCA software, where the product impact data is organized, modelled, calculated, and stored. This matters because EPDs don’t live in isolation. Background LCA reporting, assumptions, and calculations should be generated alongside the EPD, not reconstructed later. When the EPD tool sits on top of a robust LCA model, credibility and traceability are much easier to maintain.

b) How is the LCA data foundation for your environmental declarations set up?

This is one of the most important distinctions. Some tools rely on locked, generic datasets applied across products. Others let you build EPDs from data that reflects your actual manufacturing processes.

Going with the tool that offers locked datasets or AI-generated data for your entire portfolio can be a valid choice if your goal is high-level coverage or internal orientation, and if you’re comfortable with similar results across much of your portfolio.

If you want environmental declarations that can be confidently shared with customers, verifiers, and authorities without raising questions about having similar or the same numbers across your product portfolio, you may need product-specific EPDs that reflect real differences in materials, processes, or production sites.

Table: Generic, locked or AI-generated LCA models vs product-specific, customizable LCA models

| Generic, locked or AI-generated LCA models | Product-specific, customizable LCA models |

| Might be faster to set up initially, often with limited configuration | Might require longer setup upfront, but highly efficient once the foundation is in place |

| Product impact results often look identical across multiple products | Results reflect real differences between products, variants, and sites |

| Limited visibility into assumptions and data choices | Clear documentation of assumptions, data sources, and modelling choices |

| Higher risk when results are questioned by customers or competitors | Defensible results that hold up under tender and verifier scrutiny |

| Scaling to large portfolios often either becomes manual and repetitive, or impossible to do | Designed for reuse across product families and portfolios |

c) What secondary datasets are used to generate EPDs when primary data isn’t available?

No team has perfect data from day one. A strong EPD solution supports recognised secondary datasets when product-specific data is missing, and makes it clear where those assumptions are applied. Access to industry-proven databases such as ecoinvent, PEF, World Steel, or sector-specific datasets helps fill gaps without undermining credibility.

d) Can you trace product impact results back to data, assumptions, and versions for your EPDs?

Once EPDs are public, questions might come. You should be able to trace numbers back to data sources, allocation rules, and assumptions – and see what changed when a model or dataset was updated. In best-in-class EPD solutions, this version control lives in the LCA software itself, not in separate documents or spreadsheets.

e) Does automation respect EPD-specific regulatory standards?

Automation should support consistency, not shortcuts. For EPDs, that means automated calculations aligned with EN 15804 system boundaries, consistent application of allocation rules, and cradle-to-grave models built from real manufacturing data, supplier inputs, material specifications, and secondary datasets where needed.

f) How easy is it to update, recalculate, and republish your EPDs?

EPDs aren’t static. Suppliers change, energy mixes shift, PCRs evolve. An EPD solution should allow you to recalculate and republish EPDs without rebuilding models from scratch. If every update feels like starting over, the tool will become a bottleneck as requirements grow.

EPDs exist to show transparency and comparability. If your tool removes meaningful differences between products, you’re carrying reputational risk – even if the PDF itself is compliant.

2. Industry LCA expertise – how well does your EPD vendor understand your industry?

Not all EPD generators are built with construction or industrial manufacturing in mind.

Some tools are designed as generic calculators. On paper, they still produce a compliant EPD. In practice, they often deliver averaged results that flatten meaningful differences between products.

For example, let’s say you manufacture concrete products. One EPD tool produces EPDs with the same product impact result for all strength classes because they share a similar recipe structure. Another solution generates EPDs that reflect differences in cement content, additives, curing processes and energy mixes per plant. Both outputs may be EPDs, but only one tells a credible product story when a customer, verifier or tender committee looks closer.

An EPD generator built for consumer goods or high-level corporate reporting often collapses this complexity into averages. That looks fine, until it doesn’t. The cracks usually show when:

- a verifier asks why two different products have identical impacts

- a tender requires product-specific data instead of a generic declaration

- sales needs to explain why one variant performs better than another

- R&D wants to understand differences between similar products

At that point, the complexity doesn’t disappear. It lands on your desk.

If you’re a building materials or industrial manufacturer, the questions to ask your EPD software provider go beyond “can this tool generate an EPD?” Ask for customer case studies and concrete examples from companies with similar products or production setups. It also helps to request a reference call with customers who have implemented the software in a comparable context.

Pay attention to whether the vendor talks about product families, sites and verification outcomes – or only about features. If the answers stay vague, it usually means the tool wasn’t built for your level of complexity.

Did you know? At Ecochain, we’ve delivered LCA solutions for 15 years to construction and industrial manufacturers, completed over two million LCAs and published thousands of EPDs across recognised program operators. Our in‑house experts speak Dutch, German and English and sit on UN sustainability forums. This experience means we know what verifiers expect and can help you avoid pitfalls. Continue exploring: How to create, verify and publish accurate EPDs at scale |

3. Credibility and verification – Is the EPD software solution trusted by program operators?

An EPD only has value if a third-party, independent and accredited verifier is willing to sign off on it.

Why? EPDs verification is a moment where your assumptions, data choices, allocation rules and system boundaries are reviewed by someone who was not involved in creating the EPD. That independence is what gives the declaration credibility with customers, regulators and the market.

Look for EPD tools that are recognised and accepted by leading program operators such as EPD International, ECO Platform, IBU, MRPI or NMD.

Before committing to an EPD tool, it’s worth asking very explicitly:

- What is your typical first-time verification approval rate?

- Which program operators and independent verifiers do you work with regularly?

The right EPD solution will help you build something that stands up when an independent expert looks closely – and signs their name under it.

Something to consider Be cautious when an EPD software provider offers to both create and verify your EPDs. When the same organisation helps build the LCA model, generates the EPD and then verifies it, objectivity becomes questionable. Even if the intentions are good, the perception risk is real – and in many cases, independent verification is either legally required or strongly expected by program operators and customers. There is an important distinction to make here. Getting a pre-check support from your EPD solution provider before verification is valuable. It helps catch data gaps, unclear assumptions or PCR misinterpretations early, when they’re still easy to fix. What you want to avoid is having your software vendor act as the verifier itself. A strong EPD solution supports you up to verification, not instead of independent verification. |

4. Support and service – What EPD expertise comes with the software?

EPD software rarely works in isolation.

Even the best tool won’t help much if you or your team are left alone to interpret PCRs, set up data structures, or prepare for verification without guidance. And most sustainability teams don’t want (or have the time) to become LCA specialists overnight.

Strong EPD solutions pair software with the right level of expert support. Not to take control away from you, but to help you build confidence and move faster without cutting corners.

Look for vendors that have LCA expertise in-house, not just outsourced or hidden behind a ticketing system. Being able to speak directly with someone who understands your industry, your products, and verifier expectations can save weeks of back-and-forth.

Also, if the vendor offers on-demand courses and training, even better. Having experts available on demand will help a lot when you start modeling LCAs and reporting. Good onboarding helps your team understand what decisions matter and why, without forcing you to memorise methodology you’ll rarely use. On-demand training and refresher sessions become especially valuable as your scope grows.

Did you know? At Ecochain, software and service are designed to work together. Our LCA specialists help set up your data foundation, train your team in a way that fits your role, and stay available when questions come up. We support you through data modeling choices, pre-checks, EPD generation and verification preparation – while you remain in control of the outputs and decisions. Curious how this would work for your specific products or EPD requirements? Our team can help you think it through. |

5. Time needed to get your EPDs – how long does it really take to get a verified EPD?

Speed matters. But with EPDs, too much speed is often a red flag.

You’ll see tools claiming they can generate an EPD in days – sometimes even hours. That can sound appealing when deadlines are tight. The problem is that high-quality, defensible EPDs don’t come from pushing a button on generic data.

Many “fast” solutions rely on locked datasets applied across an entire portfolio, or on one-size-fits-all assumptions that smooth over real differences between products, sites, and processes. Some newer tools lean heavily on AI to automate the full process, but governance, transparency, and verification expectations around AI-generated EPDs are still evolving. Speed is achieved, but often at the cost of credibility.

That’s why the time needed to get your EPDs should be understood as a sequence of phases – not a single promise:

- Phase one: building the LCA foundation – This is where product data, supplier specifications, manufacturing processes, allocation rules, and assumptions are set up and reviewed. It takes time because this is where quality and credibility are established. If the foundation is weak or generic, the EPD may look fine on paper but struggle under verification or public scrutiny later and challenge your public reputation.

- Phase two: generating EPDs from that foundation – Once the LCA foundation is in place, generating product-specific EPDs becomes much faster. Not because quality dropped, but because the heavy lifting has already been done. This is where scale and speed actually come from.

- Phase three: pre-review and quality checks – This step isn’t mandatory, but it’s highly valuable. This is where EPD experts pre-review before formal submission (ideally your EPD solution provider has the EPD experts in-house). Early checks help catch data gaps, unclear assumptions, or PCR interpretation issues before they reach a verifier – which increases first-time approval rates and avoids delays.

- Phase three: verification (for verified EPDs) – For third-party verified EPDs, timelines also depend on independent, industry-approved verifiers. Even with perfect preparation, availability and review cycles sit outside the software vendor’s control. Unless you’re producing a self-declared EPD, no tool can bypass this step.

This is why speed claims should always be unpacked.

One important thing to keep in mind when evaluating how fast an EPD solution really is: When a vendor says they can produce a verified EPD in a matter of days, it’s worth pausing to understand what that speed is based on. Does that speed come from applying generic datasets and assumptions across a group of products? Rather than focusing only on how fast an EPD can be generated, it’s useful to also ask:

There’s no single “right” answer – only what’s appropriate for your use case. The important thing is knowing what trade-offs sit behind speed claims, so you can choose an approach that fits both your timelines and your credibility requirements. |

6. Scalability and flexibility – Can the EPD solution grow with you?

The first EPD is rarely the problem.

The challenge usually shows up later. When one declaration request turns into many. When sales wants EPDs for more than just bestsellers. When a second factory comes online. When a new market asks for localised data. Or when program operator rules evolve and yesterday’s setup no longer feels future-proof.

This is where EPD solutions start to diverge.

When we talk about scalability in EPD software solution, you’re really looking at three connected things:

- EPDs at scale – how easily you can expand coverage as requirements grow

- Verification at scale – whether verification effort and cost stay under control

- Reuse and flexibility – whether earlier work becomes a foundation or a bottleneck

Traditional approaches treat every EPD as a fresh project. New model. New checks. New verification effort. That can work for a single product, but it quickly becomes unmanageable once EPD demand grows across a portfolio. Scalable EPD solutions allow you to build a solid foundation once and then expand incrementally and create EPDs at scale, without rebuilding everything each time. Instead of modelling and verifying per product, they rely on reusable structures – product families, factories, shared processes – that reflect how manufacturing actually works.

Verification at scale is where this difference matters most. Traditional verification models help you verify each EPD, every time, at full cost. That means timelines and budgets grow linearly with volume – predictable, but not sustainable. EPD software designed for scale supports verification at a higher level – for example at the factory or model level – and allows multiple product-specific EPDs to be generated from that verified base. When done properly, this enables a verify-once, pay-once approach, where new EPDs can be published on demand without reopening verification for every product.

This approach affects how fast you can respond to tenders, how confidently you can commit to broader EPD coverage, and how often you have to go back to leadership for additional budget.

Flexibility of your EPD software solution ties all of this together. A future-ready EPD solution should allow you to reuse data, logic and assumptions as your scope expands – whether that’s new products, additional sites, or changing reporting requirements. If growth automatically means rework, scalability was never designed in.

Before you invest in your new EPD software solution, it helps to ask your vendor a few overarching questions about scale:

Clear answers usually signal a solution that will support your growth, not quietly limit it. |

7. ROI and total cost of ownership – what does an online EPD software really cost as you scale?

Many EPD solutions look affordable at the start. The costs only become clear later, when every additional EPD requires new setup, new verification, and new spend. At that point, the question isn’t whether the tool works but whether the approach still makes financial sense.

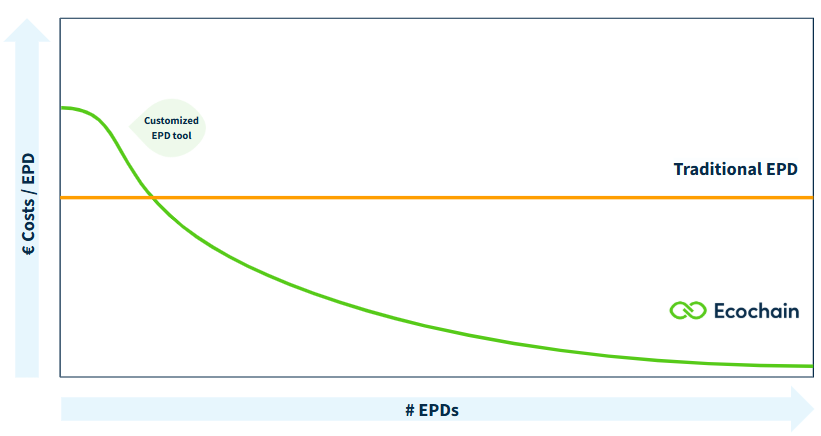

In practice, EPD solutions follow two very different cost models:

- Some treat each EPD as an isolated unit. New product means new work, new verification, and a similar cost every time. The price per EPD stays flat, no matter how many you produce.

- Others are built around reuse. You build a solid LCA model foundation, then generate product-specific EPDs from that base at a much lower marginal cost. As volume grows, the cost per EPD drops.

| Aspect | Traditional per-EPD approach | EPDs at scale solutions like Ecochain |

| LCA setup effort | Repeated for every product | Reused across products and variants |

| Portfolio feasibility | Limited to one or a few products | Realistic for full portfolios |

| Verification | Each EPD verified separately | Verify once at model or factory level, then publish verified EPDs on demand |

| Cost per EPD (at scale) | Stays high | Drops significantly as volume grows |

| Budget predictability | Low – grows linearly with volume | High – costs flatten over time |

What does this look like in practice? Traditional EPD consulting vs Ecochain’s EPD solution

With traditional consulting approaches, each EPD is treated as its own project. That means new modeling work, new verification, and a similar cost every time. The cost of traditional EPD approaches is usually around €10,000–€15,000 per EPD, and expenses scale linearly with volume.

So when requirements grow, the numbers add up fast:

- 10 EPDs → €100,000–€150,000

- 100 EPDs → €1,000,000–€1,500,000

- 500 EPDs → €5,000,000+

With Ecochain, you can set up and verify an LCA foundation at factory or portfolio level. From there, product-specific EPDs are generated from the same LCA base. At scale, our customers generate EPDs for as low as €50 per report.

That means, for 500 EPDs, with Ecochain you’re looking at a total cost of ~€25,000, compared to €5,000,000+ using traditional approaches.

Same outcome – verified, compliant EPDs. Completely different economics that helps you determine whether full EPD coverage across your portfolio is even realistic.

To assess ROI of your EPD generator properly, it helps to look beyond list prices and ask a few focused questions:

|

The LCA software solution you choose for EPD generation is the ceiling you build above your business

You don’t just want to create EPDs. You want to move the needle.

And that means:

- Finding a partner who understands your products, accelerates your compliance and positions you for future regulation

- Building a reliable product footprint data foundation

- Empowering yourself to have all the answers and EPDs ready for your sales and product teams to use them

- Building a systems that can easily scale from one to hundreds of EPDs without rework or seeing your costs go through the roof

- Establishing yourself as an expert in the company, earning trust from verifiers, leadership, and customers

That’s exactly what Ecochain helps you do.

We’ve helped 450+ manufacturers in construction and industrial sectors generate thousands of verified, high-quality EPDs at scale – not by replacing you with AI, but by putting you in control of a system that actually works and sets you up for long-term success, no matter the level of complexity or scaling challenge you have to deal with.

Whether you’re building your first EPD or scaling across 50 product lines, we’d love to show you how Ecochain works.

Book a demo or Explore EPD automation to get started.

Frequently asked questions

What an “EPD generator” actually is – and isn’t

An EPD generator is a tool designed to help you create Environmental Product Declarations by structuring product data, applying LCA models, and preparing outputs for verification and publication.

The challenge is that the term is used very loosely. In practice, an “EPD generator” can refer to very different things, including:

- a spreadsheet template with built-in calculations

- a generic LCA tool that can export results in an EPD format

- an AI-based calculator that fills in averages

- a full LCA automation platform purpose-built for EPD generation

All of these may produce something that looks like an EPD. But the difference lies in what happens before the PDF is created.

A credible EPD is the outcome of:

- how product and manufacturing data are structured

- how LCA models are built and reused

- how system boundaries, assumptions, and allocation rules are applied

- how verification is prepared and supported

If an EPD tool focuses mainly on generating the final document, everything upstream – data quality, modelling choices, traceability – often becomes manual work and risk for your team.

That doesn’t mean every business needs the most complex solution on day one. But understanding what an EPD generator actually covers – and what it leaves to you – makes it much easier to choose a tool that fits your needs today and still holds up as EPD demand grows.

Is there a software I can use to generate EPDs quickly?

Yes – there is software that can generate EPDs quickly. The important question is what “quickly” is based on.

Some EPD tools achieve speed by applying generic datasets, averages, or pre-filled assumptions across products. That can be useful for early estimates or internal orientation, especially when you need fast coverage and are comfortable with limited product differentiation.

Other EPD solutions focus on building a reusable LCA foundation first – based on your manufacturing processes, material specifications, and supplier data – and then generate EPDs quickly from that verified base. In this case, speed comes from reuse and automation, not from simplification.

If you’re aiming for product-specific, third-party verified EPDs that will be used in tenders, shared with customers, or reviewed by authorities, speed usually improves after the LCA foundation is in place. Without that foundation, very fast EPD generation often means relying on generic assumptions rather than reflecting how products are actually made.

A useful way to think about it is this: EPD software can make generation fast – but credibility comes from what’s already been modelled.

When evaluating “fast” EPD solutions, it helps to ask:

- Are results product-specific or averaged across a portfolio?

- What data is reused versus newly created?

- What level of scrutiny are these EPDs expected to hold up to?

That context makes it much easier to decide whether a fast EPD solution fits your goals – now and as requirements grow.

When should I use an EPD generator?

You should consider using an EPD generator when Environmental Product Declarations are no longer a one-off request, but something your business needs to deliver repeatedly, reliably, and at scale.

This typically happens when customers ask for product-specific EPDs, sales needs them for tenders, regulations tighten, or you need to cover more than a single flagship product. At that point, generating EPDs through ad-hoc spreadsheets or one-off consulting projects quickly becomes slow, expensive, and hard to maintain.

An EPD generator makes sense when you want a more structured, repeatable way to create verified EPDs – without rebuilding everything from scratch.

What should I be looking at when buying a construction EPD software?

When evaluating EPD software for construction products, look beyond whether it can generate a compliant declaration.

The most important factors are whether the tool supports product-specific data, traceability for verification, and reuse at scale. That includes how the software models real manufacturing processes, handles product variants and sites, works with recognised datasets, and prepares EPDs for independent verification.

It also helps to assess how the solution scales over time – how easy it is to update the models and re-generate EPDs when data or PCRs change, how verification effort behaves as volume grows, and whether support is available when your team needs it.

In short, the right EPD software should help you move from one-off EPDs to a repeatable, credible way of managing product sustainability data across your portfolio.

Do I need LCA expertise in-house to use EPD software?

No, you don’t need to be an LCA expert to use EPD software effectively. But you do need access to LCA expertise at the right moments.

Good EPD software is designed to guide non-experts through the process, with built-in structure, standards alignment, and safeguards that reduce the risk of methodological mistakes. This allows sustainability managers, product specialists, or R&D teams to work with EPDs without becoming LCA specialists overnight.

That said, some level of expertise remains important. Decisions around system boundaries, allocation rules, data quality, and PCR interpretation still require experience, especially when EPDs are verified or used in tenders.

This is why many manufacturers choose solutions that combine software like Ecochain, with in-house LCA expert support. The software handles repeatability and scale, while experts step in for data setup, reviews, and verification preparation when needed.

In practice, the most effective setup isn’t “software only” or “consultants only”. It’s a hybrid approach where your team stays in control of data and outputs, supported by experts when decisions really matter.

Should I be looking for an EPD generator that offers LCA expert support?

- onboarding tailored to your industry and product types

- access to real LCA and EPD experts, not only generic helpdesk support

- on-demand training on LCA methodology, EPD generation and how to use the software

- services that cover data structure, pre-review and verification preparation

- support available in your local language

What questions should I ask before buying an EPD tool?

Before buying an EPD tool, focus on 6 key questions that reveal how the solution will hold up beyond the first few declarations:

- Can the tool produce product-specific EPDs, or does it rely on generic or averaged data?

- How easy is it to trace results back to data, assumptions, and allocation rules when a verifier or customer asks?

- What happens when something changes – suppliers, energy mixes, PCRs – can EPDs be recalculated and republished without starting over?

- How does verification work at scale: per product, or from a reusable, verified foundation?

- How do costs and effort change as the number of EPDs grows?

- What level of expert support is available when your team needs help?

Clear, concrete answers to these questions are usually a good indicator of whether an EPD tool will support your business long term – or create friction as requirements grow.

How can I automate EPD creation with Ecochain's solutions?

You automate EPD creation with Ecochain by setting up your product and manufacturing data for your whole facility, factory or plant once, and reusing it across your product portfolio.

This means you upload your manufacturing data, product specifications and any necessary secondary datasets into the software. From there, Ecochain handles the complex work in the background: impact calculations, standard-compliant modeling, data checks and EPD report generation.

Before submitting your EPDs to verifiers, Ecochain’s LCA experts review the EPD to flag issues early and reduce friction during third-party verification. When needed, we also support EPD publication through recognized program operators and can help tailor the front page of your EPDs to match your brand.

The result is a repeatable process: once your data foundation is in place, you can generate and publish thousands of EPDs quickly and consistently, without starting from scratch each time.