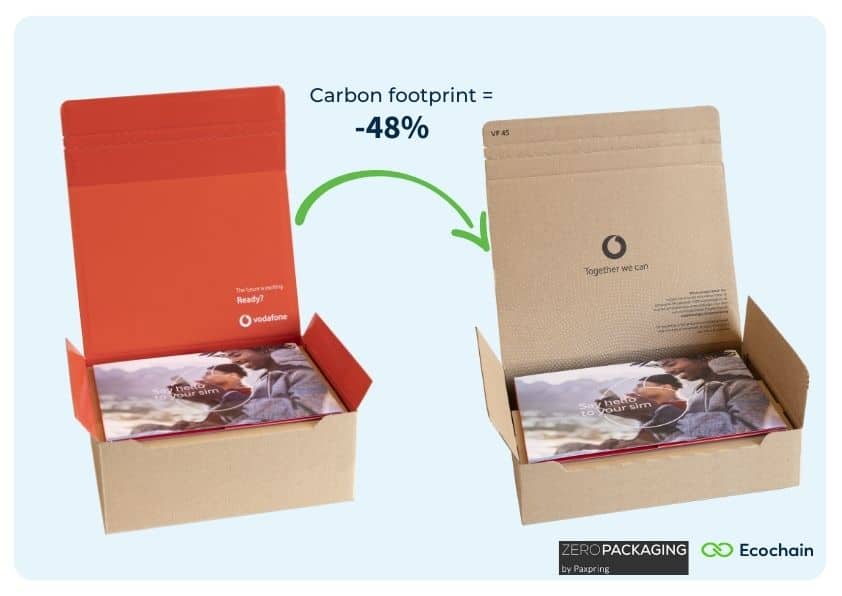

How ZeroPackaging reduced the carbon footprint of Vodafone’s packaging by 48%

ZeroPackaging – an initiative by Paxpring, designs and delivers complete, eco-friendly packaging solutions. With a wide variety of customers like Samsung, Fairphone, Vodafone, etc – they offer tailored sustainable packaging in e-commerce, fashion, and consumer electronics.

ZeroPackaging shows the market that amazing quality & low environmental impact – go hand in hand.

But they don’t ‘just’ want to make these environmental claims. They design sustainable solutions completely driven by environmental data.

This is how.

ZeroPackaging has great knowledge of the effects of different materials and changing processes on designs. But to make real environmentally friendly decisions – you need a credible impact methodology and solid environmental data as groundwork for your design.

They want to be able to put the environmental impact of all their possible designs to the test.

ZeroPackaging notices the industry mainly seeks plastic-free solutions. But with multiple environmental crises lurking around every corner, offering plastic-free solutions alone isn’t enough for them.

ZeroPackaging wants to answer the balance between industry demand and sticking to true climate impact reduction. Giving customers transparency on the full environmental picture of their design. And enable optimal sustainable decision-making for all parties involved.

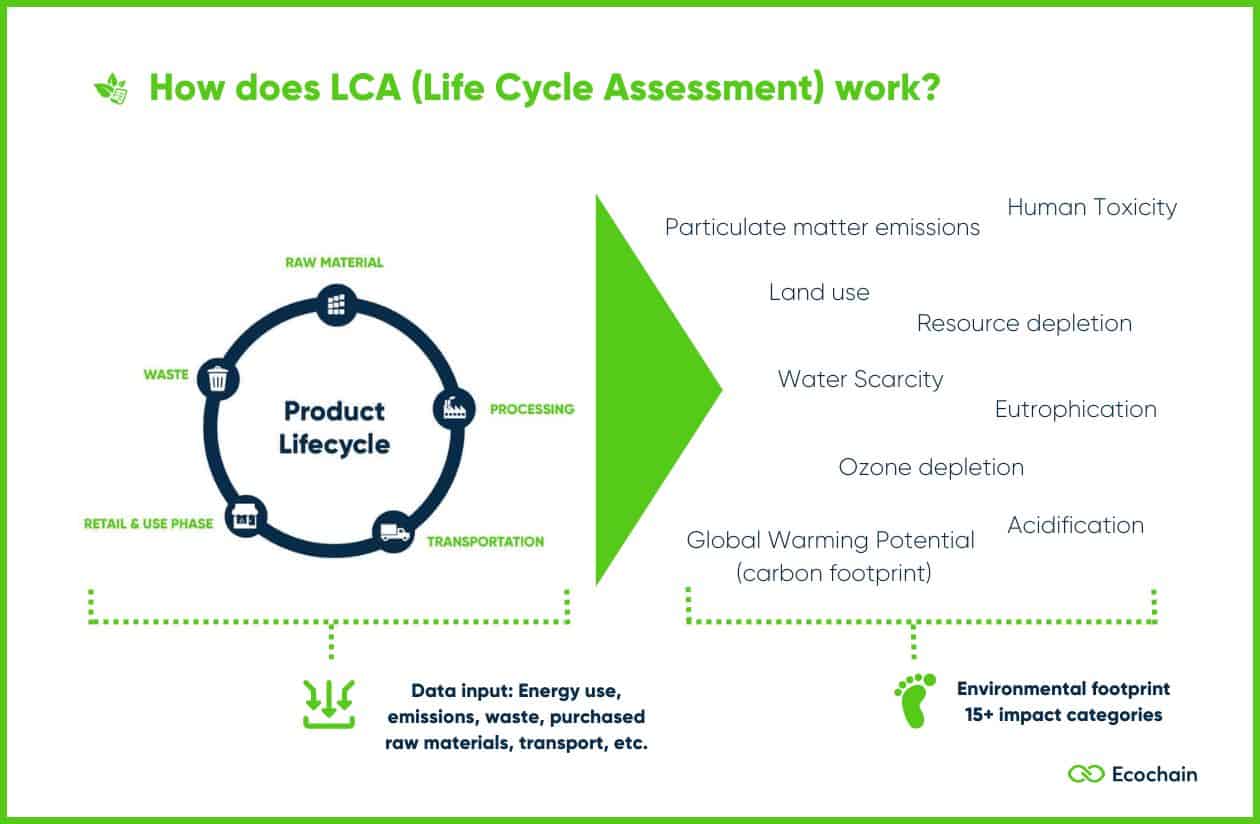

The best way to do so? Measure the full environmental footprint of their tailored designs – using the scientific footprint method Life Cycle Assessment (LCA).

We believe that making true sustainability visible – contrary to just the marketing side of sustainability – is needed for the future. Resulting in new business opportunities too.

- Thomas van Hemert, Designer at ZeroPackaging

A Life Cycle Assessment measures the environmental impact of all the life phases of a product (from raw materials to manufacturing/production, to transport, to customer use, to the end-of-life). Revealing 15+ environmental impact outcomes: your product’s footprint results.

Environmental data is crucial to make sustainable design decisions. As it shows you where your product’s biggest impact ‘hotspots’ lie. It’s the foundation for the design approach and equally named European Directive ‘Ecodesign’. Ecodesign means using LCA results in design to effectively reduce a product’s environmental impact throughout every phase of its lifecycle.

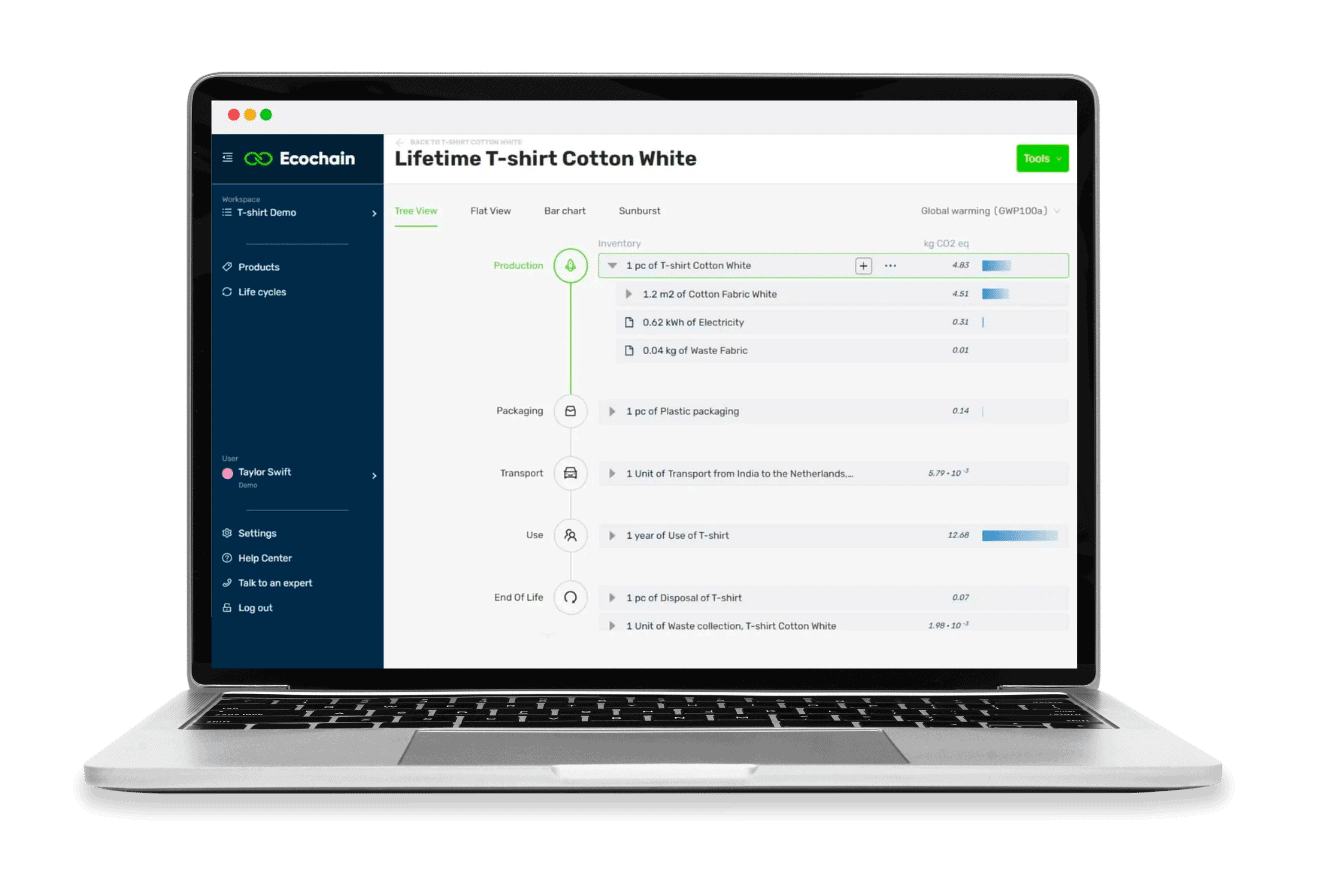

ZeroPackaging has sustainability integrated into its DNA. But, to fully embrace data-driven sustainable design, LCA needs to be accessible at all times. They need LCA software that’s user-friendly, credible, and easy to integrate into their design processes.

ZeroPackaging chose Ecochain’s product footprint tool Mobius to fulfill two main goals:

What does this look like in practice?

The main functionalities of Mobius combined with how easily the tool can be tailored for packaging, makes working with Ecochain a great partnership.

- Thomas van Hemert, Designer at ZeroPackaging

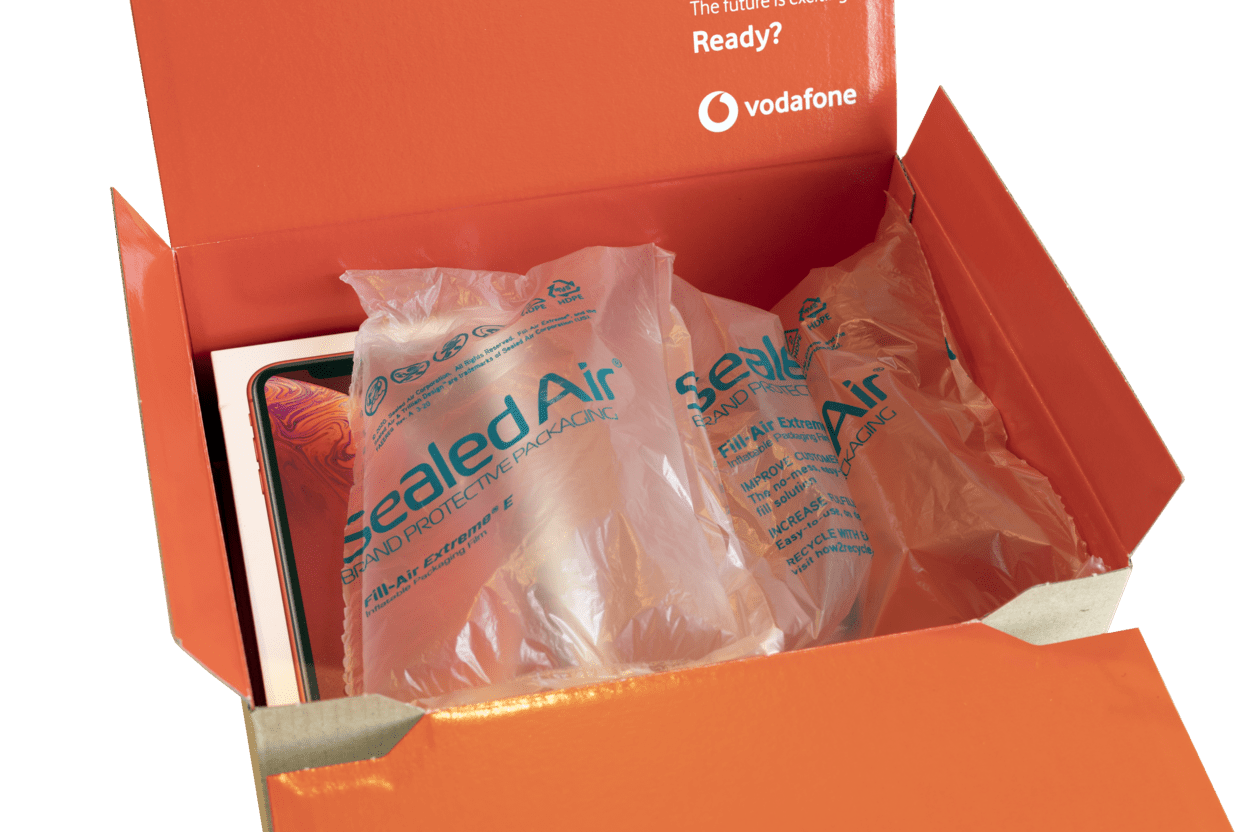

ZeroPackaging’s customer Vodafone wanted their signature package, in which they ship their products (e.g. mobile phones), to be more sustainable.

ZeroPackaging improved Vodafone’s packaging design through 3 phases:

Vodafone’s initial packaging is critically analyzed. The packaging only uses a few materials:

ZeroPackaging’s design proposal: the carbon footprint of Vodafone’s packaging could best be reduced by:

Let’s put it to the test in Mobius.

After measuring both the old and new designs in Mobius, ZeroPackaging found the printing technique (paper thickness + ink) to be a relatively big impact hotspot too. So they use:

Kaizen is a Japanese term meaning ‘change for the better’ or ‘continuous improvement’. It is a business philosophy that concerns the processes that continuously improve operations and involve all employees. Sustainability to us truly is a key aspect of Kaizen

- Thomas van Hemert, Designer at ZeroPackaging

We can’t wait to see what else they have in store.