We always talk about why you should engage your suppliers in your emission reduction efforts. But how do you actually retrieve the primary environmental data you need from them?

Let’s dive into it.

GHG Protocol reporting in the EU’s new CSRD

The EU’s new Corporate Sustainability Reporting Directive (CSRD) will affect more than 50.000 large companies in Europe from 2025 onwards. And will- almost certainly- require reporting according to the Greenhouse Gas (GHG) Protocol.

The CSRD highlights the importance of measuring the GHG emissions of a company’s complete value chain (upstream + downstream). As this is where up to 80% (!!) of a company’s footprint can lie.

These kinds of emissions are also called scope 3 emissions, in GHG Protocol terms.

Scope 3 category: Purchased goods & services

To make sure your scope 3 emissions are as accurate and representable as possible. You will also need primary GHG data from your suppliers (upstream).

The GHG Protocol divides scope 3 emissions into different categories– covering various upstream and downstream emissions (e.g. use of products by consumers). Here, primary GHG data from your suppliers falls under scope 3, category ‘purchased goods & services’. Which is the scope we cover in this guide.

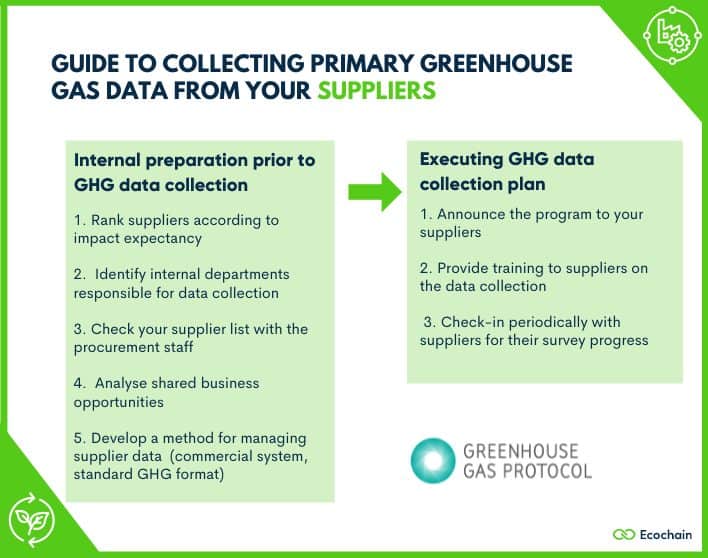

Collecting GHG data from your suppliers: two phases

As the GHG Protocol describes, the supplier data collection can be divided into two phases. An internal planning phase and an execution phase. A quick summary:

1. Internal planning phase:

Collecting primary data from your suppliers can be…quite a project. It requires a clear strategy and planning. Think of; ranking suppliers, assigning internal responsibilities, and how to collect the data.

2. Execution phase:

This is where you announce the program to your supply chain and start the data collection process. This means; training your suppliers and monitoring their progress.

Let’s go through these phases step-by-step.

Phase 1. Internal preparation prior to supplier GHG data collection

1. Rank suppliers according to high impact expectancy

Many companies have a LOT of suppliers. And some of these suppliers play a larger role in your supply chain processes. Either because of the impact-heavy materials used in their products and services, high sales numbers, transport distances, etc.

These suppliers form the biggest risk to your environmental footprint and therefore, the highest potential for emission reduction. Your efforts should ALWAYS be focused on them.

Start with measuring your company’s baseline GHG performance. This is done through measuring your company footprint– which also includes 16+ other environmental impact outcomes. Your baseline, will show the initial overview and size of your scope 1, 2, and 3 emissions. Ensuring you don’t base your process on loose assumptions. Collect the following information of these high-impact suppliers:

- Supplier name

- Supplier address

- Procurement contact

- Supplier type (e.g., production-related, non-production related)

- Commodity or service type

- Annual spend

2. Identify the internal departments responsible for data collection

Are you currently already surveying your supply chain through other environmental or social responsibility initiatives? If not, look for the perfect internal departments to do so and assign a program manager/responsibility.

Usually this is a combination of the sustainability- and procurement staff. With someone from sustainability as project manager.

3. Check your supplier list with the procurement staff

When the first supplier list is completed, make sure it’s reviewed by your procurement staff. Are your assumptions correct?

Your procurement staff knows exactly what goes on in your supply chain. So, they play an important role in communicating with suppliers during the data gathering process. Ensure to educate them on the program, its relevance, the data collection framework, and how to explain the program to suppliers.

4. Analyse shared value opportunities

Collecting GHG data (or any environmental data) from your suppliers can lead to many business opportunities. Not only your company could benefit from an improved footprint. Look for ways in which you can create shared value with your suppliers. Collaborations, competitive advantages- what could be possible business opportunities for them?

You can use these opportunities as leverage to get suppliers on board with the GHG data collection.

Read more about how to create shared value with suppliers here.

5. Develop a method for managing supplier data

There are several options available for collecting and managing data:

a. Use a (commercial) data collection system:

If you already use a GHG measurement system- or are searching for one. Make sure your suppliers can use the same tool. This helps:

- Collect and keep all the primary data in one place.

- Makes supplier data immediately available, eliminating extra work because of chaotic datastream structures.

- Ensures you will receive the same high quality environmental data.

For example, large companies in our portfolio use Ecochain’s Environmental Intelligence Platform as their footprinting tool and data collection system for their suppliers. The biggest suppliers receive training on how to use the software themselves. They do their own GHG measurement and the results automatically flow back into the platform. Immediately ready for use.

b. Use a standardized GHG reporting format:

If you don’t have a GHG measurement system in place that your suppliers can use. You should collect primary data by using an existing standardized GHG reporting format. However, keep in mind that many suppliers themselves don’t have a system in place for GHG measurements. This will most likely slow down your process.

According to the GHG Protocol, this reporting format should include:

- Description of emission sources and scope

- Boundary details

- Reporting period

- Activity data and GHG emissions in CO2-eq

- Comparability with previous years GHG calculation methodologies

- Details of emission factors and data sources

- Discussion of uncertainties

- Trends evident in data (if applicable)

- Progress towards targets (if applicable)

- Description of events affecting data (if applicable)

- Ratio indicators needed for allocations (Ratio indicators provide information on performance relative to a business type and can facilitate comparisons between similar products and processes over time.)

- And any other relevant information

Note: Emissions data from your suppliers can be confidential or exclusive. Make sure to check this with your suppliers (e.g. non-disclosure agreements) and manage your data collection process in a confidential way. Preferably according to ISO 27001.

Phase 2. Executing GHG data gathering plan with suppliers

1. Announce the program to the supply chain

Once your GHG Reporting system is in place and your supplier list set. It’s time to let your suppliers know about it. Start with sending an email explaining:

- The program and its relevance;

- Consequences for not participating (tone of voice depends on relationship with suppliers of course);

- How the data will be collected & used (briefly explain the GHG system/reporting format);

- Available resources that will help with the collection (contact person, training, implementation, proposed measurement system, etc.);

- Data protection details;

- The project overview and timeframe;

- Plan a kick-off call/meeting to discuss details, responsibilities, possibilities for business opportunities, etc.

2. Provide training on the data collection process

Having your suppliers use a new GHG measurement system requires training and guidance.

After both you and your supplier(s) have decided on the main contact person/person responsible at your supplier. Make sure they receive a full training and/or some knowledge sessions on how to use the GHG measurement system.

How extensive this training needs to be- depends on the GHG knowledge level already present in your supplier’s company. Some companies make the data collection a close collaborative process.

3. Check-in periodically with suppliers regarding their progress on completing the survey

If you and your suppliers work in the same GHG measurement system, this step is less necessary. With a clear project overview, close communication and an automatic data input. Your supplier’s process is always transparent.

If you are gathering your suppliers’ GHG data in a standardized GHG reporting format, check-in is necessary. Especially, since your suppliers often have to work with a new GHG measurement tool or consultancy partner. Separate data gathering processes, simply means more alignment.